Sterling to Display Site Access Solutions

Sterling, which is exhibiting at the IEEE PES T&D Conference and Exposition, manufactures site-access solutions. The flagship TerraLam CLT mat is an engineered solution that brings many advantages over conventional timber or bolted mats, such as cost and time savings, according to the company.

Manufactured in Illinois and Texas from sustainable American-grown SYP trees, TerraLam helps protect the environment by distributing weight better across the ground to reduce compacting and pumping, eliminating rutting and other damage caused by heavy equipment, and cutting carbon emissions by up to 50%, by halving the number of trucks needed to deliver mats. This reduction also helps improve the bottom line with up to 50% lower freight costs and keeps projects on schedule with faster deployment of your temporary road.

TerraLam’s advantages are achieved through manufacturing to produce an engineered highly consistent, durable, and relatively lightweight mat that covers twice the linear footage of a traditional timber mat while offering the same toughness.

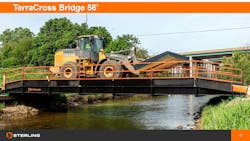

Additional enhancements for certain applications include edge reinforcements for increased durability and advanced mold and fungal inhibitors for humid locations. The mats are available in a few thicknesses for different ground conditions, including for use in the company's TerraCross temporary bridge solutions.

For more information, visit the website.