Since the 1970s, Tokyo Electric Power Co. (TEPCO) has been extending its extra-high-voltage (EHV) transmission network in the center of Tokyo, Japan, to supply the increasing power demand. From the inner and outer circle of bulk power transmission systems that surround Tokyo, many of the 275-kV and some of the 500-kV power cable circuits are installed in the city’s metropolitan areas. The majority of the EHV substations in these areas are located in the basement of buildings to maintain environmental harmony with the adjacent streets.

The practice of installing underground substations also is a business decision providing an effective use of the city’s land. It minimizes the long-term loss of tenant income to the property owners that would occur if the substation was sited at ground level. Alternatively, there are instances within the city where a redevelopment project leads to the need to replace an existing underground substation with a larger-capacity substation to supply the increased demand for power.

In the construction of an underground substation in dense urban areas, the most important consideration is disaster prevention. Another consideration is decreasing the floor-to-ceiling height of the underground substation, which can reduce the total cost of construction significantly. In these situations, the installation of large-capacity gas-insulated transformers (GITs) in underground substations is a key factor. Apart from the reduction in total construction costs, underground substations with GITs are designed to provide a reliable level of disaster prevention and a stable electric power supply to the city.

Features and Advantages

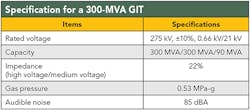

The large-capacity GITs are designed with high gas pressures (0.53 MPa-g [77 psi-g]) to improve the insulation and cooling capacity. However, GITs with a capacity not exceeding 100 MVA use comparatively low gas pressures (0.12 MPa-g [17 psi-g]).

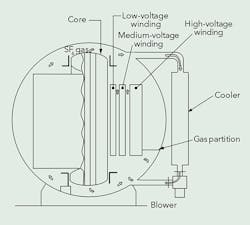

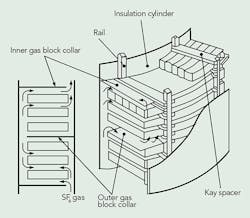

The GIT’s core and winding consist of a simple structure similar to that used in conventional oil-immersed transformers. The core and winding are cooled and insulated by high-pressure SF6 gas. Taken from the lower side of the tank, the gas cools the core and winding, is collected in the upper part of the tank and is returned to the radiator and cooled. The transformer has a disc-type winding, and the internal gas flows in a zigzag line by the gas stop collar. An excellent polyethylene terephthalate (PET) film, which is relatively heat-proof when compared with the insulating paper, is applied to the stranded winding insulation.

Large-capacity GITs have several advantages:

• Only nonflammable materials are used; hence, there is no need for special firefighting facilities in the substation.

• GITs have excellent nonexplosive performance. In the event of an internal failure, the design and structure enclosing the compressible gas are superior to that used in the design of oil-immersed transformers. Therefore, nonflammable and nonexplosive characteristics make GITs the safest large transformers.

• Unlike oil-immersed transformers, GITs are a conservator-free structure, reducing the overall height of the transformers. In practice, this results in a 2-m to 2.5-m (6.5-ft to 8.2-ft) reduction in the height of the transformer chambers. Also, it is not necessary to install an oil basin or bung under the transformer. In addition to reducing the substation construction costs because of the lower height and smaller area required for the transformer chambers, there is no potential hazard from oil spills.

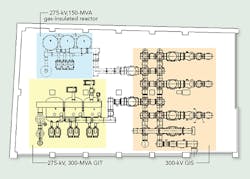

• GITs can be installed together with gas-insulated switchgear in the same room because similar SF6 gas pressures are used in these components. This can provide high compactness and flexibility in the design layout of the substation.

•Gas-insulated on-load tap changers (OLTCs) with vacuum interrupters are used on GITs. This also contributes to the nonflammable characteristic of GITs and makes maintenance work easy. Moreover, the installation of large GITs in suburban areas with mountainous districts and in environmental protection areas has removed the anxiety of oil spills. Substations equipped with GITs have been positioned to supply railway and private organizations.

TEPCO’s Experience

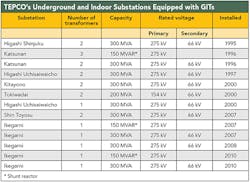

TEPCO has been installing large-capacity GITs and gas-insulated reactors for underground EHV substations in the Tokyo metropolitan area since 1989. TEPCO’s operational experience associated with GITs now totals 172 years, based on the number of GITs and days in service, without a major failure.

In the construction of underground substations, the large-capacity GIT is an indispensable technology combining safety and compactness while significantly reducing the cost of constructing a substation. Because of all the advantages GITs provide, they are regarded as a key component of underground substations in central Tokyo. TEPCO is now constructing a large number of underground substations with GITs.

Future Outlook

GITs are planned for renewal projects in urban area locations where aging transformers at EHV substations are being replaced. The large-capacity shunt reactor with capacities ranging from 150 MVAR to 200 MVAR can be manufactured using the same technology. Therefore, nonflammable, nonexplosive and compact gas-insulated substations are realized by a combination of gas-insulated components.

As a result, the reliable power supply now installed in the city center of Tokyo city is secured. Gas-insulated technology can be used for uprating voltage and capacity projects because the development of GITs will continue to be lighter and more compact compared with existing designs of oil-immersed transformers.

TEPCO is technically supporting the plan and practice to install underground substations equipped with GITs. This decision is based on the utility’s operational experience of these units and the benefits offered in terms of compactness, inherent safety and cost savings attributable to the reduced cost of construction and maintenance.

Hiroyuki Nakajima ([email protected]) is deputy manager of the substation engineering group in the transmission department of Tokyo Electric Power Co. in Japan. He joined the utility in 1995 and was previously engaged in work related to engineering and the development of substation equipment. Nakajima holds BSEE and MSEE degrees from Ibaraki University.

Mentioned in this article:

TEPCO | www.tepco.co.jp/en/index-e.html