Island Connections: Horizontal Directional Drilling in South Carolina

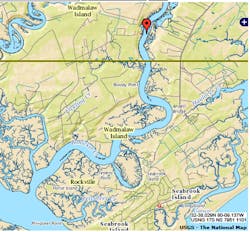

A new 115-kV transmission line was needed to increase reliability of service to Johns Island and Wadmalaw Island, both located near Charleston, South Carolina, U.S. Central Electric Power Cooperative Inc. (CEPCI) owns the statewide electric system that provides electric service to all 20 of South Carolina’s electric co-ops, including Berkeley Electric Cooperative Inc. (BEC), which provides retail electric service to the residents of both islands. The new transmission line had to cross Bohicket Creek, a waterway approximately 3400 ft (1036 m) wide, including extensive marshlands. An overhead crossing was not feasible, requiring CEPCI to evaluate underground and underwater options.

Although almost all the transmission-voltage cable crossings to islands along the South Carolina coast use high-pressure gas-filled (HPGF) pipe-type cables, CEPCI’s evaluation concluded an extruded-dielectric cable would be preferable because of the reduced chance of environmental damage and lower maintenance requirements — an important consideration because of the remote location of the line. The crossing begins on a street within a Habitat for Humanity community on Johns Island and ends in a gated residential community on Wadmalaw Island.

Installation on the water bottom was ruled out because of the environmental sensitivity of the area, including more than 1500 ft (457 m) of protected seagrasses in marsh areas. Therefore, horizontal directional drilling (HDD) was selected for the project.

Project Scope

This HDD crossing project was CEPCI’s first underground transmission cable project. The utility retained Power Delivery Consultants Inc. (PDC), a cable specialist firm, for the project. PDC developed the general scope:

- Obtain available information on the area of the crossing and potential connection locations to overhead lines.

- Evaluate use of pipe-type vs. extruded-dielectric cable.

- Retain a design firm to manage the extensive environmental and civil work.

- Have that firm perform detailed civil analysis, including multiple geotechnical bores, to determine the best entry and exit locations and the best drill path.

- Prepare a 90% design for the civil and electrical work with an emphasis on environmental concerns.

- Prepare a description of project work and obtain qualifications and expressions of interest from civil and electrical contractors.

- Prepare technical and procurement specifications, issue to qualified firms and evaluate bids, resolve questions, and send request for technical and economic approval to the U.S. Department of Agriculture’s (USDA’s) Rural Utilities Service (RUS).

- Award contract and kick off construction.

Environmental Concerns

Several areas of environmental and social sensitivity for the potential crossing were addressed in the permitting and design stage as well as during construction operation:

- Coastal seagrasses are protected in South Carolina. Initial work included mapping the seagrass areas along potential alignments and following the state’s best management practices for working in coastal seagrass areas, including extensive stormwater control programs.

- The state is protective of its Grand Oak trees — southern live oak trees with trunk diameters greater than 24 inches (610 mm).

- An Angel Oak tree near construction was estimated to be 400 years to 500 years old. Grand Oak trees were protected on both sides of the crossing, requiring minor changes to the project alignment and protective barriers outside the tree drip lines.

- Stormwater runoff was controlled carefully and monitored during construction operations.

- Construction noise was minimized on both sides of the crossing, and care was taken to avoid tracking mud from the construction areas onto the roadways.

Multiple permitting authorities were involved. CEPCI and Haley & Aldrich Inc. (H&A), the environmental and civil consultant on the project, coordinated to address the permitting requirements and applications for numerous agencies:

- U.S. Fish and Wildlife Service

- U.S. Army Corps of Engineers

- U.S. Coast Guard

- Fish and Wildlife Conservation Commission

- South Carolina Department of Health and Environmental Control’s Office of Ocean and Coastal Resource Management

- South Carolina Department of Natural Resources

- State Historic Preservation Officers and Tribal Historic Preservation Officers

- Charleston County

Close cooperation among CEPCI, its consultants and the construction contractors, Mears Group Inc. and New River Electrical Corp., ensured permitting and environmental control proceeded smoothly, with minimal delays in approving and implementing the project.

HDD and Duct Design

H&A’s analysis of soil borings along the alignment showed a depth of about 54 ft (16.5 m) below the water bottom would be in a geological formation known as Cooper Marl, and it had ideal civil and thermal properties for the planned 24-inch diameter bore. PDC’s cable rating calculations verified the desired 800-A rating could be achieved with cables at that depth. H&A determined the preferred bore entry and exit locations to avoid the marsh areas, and it performed calculations for expected drilling conditions and installation of the cable ducts. These calculations were confirmed by the HDD contractor as part of the 100% design of the project.

Details of the drill were as follows:

- 323,000-lb (146,510-kg) thrust and pullback drill rig was placed on Johns Island.

- Gyroscope steering system provided guidance of the pilot hole to improve the navigation ability of the HDD contractor.

- 1700-ft (518-m) pipe laydown area was staged in the existing overhead line right-of-way on Wadmalaw Island.

After difficulties arose in the initial stage of the pullback operation, the contractor elected to increase the bore diameter to 32 inches (813 mm).

Drilling went well, although unusual resistance was encountered pulling back the duct bundle. The bundle was removed and the bore size increased. With those changes in place, pullback was uneventful aside from a minor inadvertent return area near the drill entry point, which was quickly plugged and cleaned.

HDPE ducts were selected for both the power and communication cables. The four 8-inch (203-mm) diameter HDPE cable ducts (including one spare) had an uncased borehole. There were two 3-inch (76-mm) communication ducts. Duct bundles were made up using butt-fusion welds along a recently upgraded 115-kV overhead right-of-way on Wadmalaw Island. Extensive clearing and crane matting was required to accommodate multiple trips with heavy equipment over areas with unstable ground.

After pressure testing, the ducts were bundled together and connected to a pulling head, to be pulled by the drill rig. Two 1700-ft strings were assembled, and the pullback stopped for several hours to allow joining the strings.

Cable System Design

Historically, HPGF pipe-type cables have been chosen for crossings such as this because they can be installed splice-free for lengths greater than 1.5 miles (2.4 km) and a bore diameter of only 12 inches (305 mm) or so is required for the 8-inch steel cable pipe that contains the three phases. The pipe is rugged and pipe-type cable has an excellent and long history with HDD crossings as well as land installations. However, potential pipe corrosion could allow leaks of the 200-psig nitrogen pressure necessary to maintain electrical integrity of the paper insulation, which was a concern because cable failure would require replacing all three phases. HPGF cables require a cabinet for monitoring nitrogen pressure and communications for sending alarms to the utility as well as an alternating-current (AC) power supply for a cathodic protection system. This was not feasible for the remote location of the circuit.

Extruded-dielectric cables have a shorter operating history and require a much larger bore to accept the ducts that contain the individual cable phases. The bore is more expensive and time consuming, and it can add to the complexity of the HDD operation. However, there are no reliability and environmental concerns about corrosion and leaks. Additionally, individual phases can be replaced if there is a failure, and it is straightforward to add a spare duct or even a spare cable.

The HPGF option would require at least one splice — a trifurcating joint to separate the three phases in the 8-inch (20.32 cm) steel pipe into individual phases in stainless steel riser pipes to reach the terminations. In contrast, for extruded-dielectric cables, 3400 ft (1.04 km) or even longer can be installed termination-to-termination without the need for splices. No auxiliary equipment, ac sources or communications channels would be required. There are many more cable suppliers and installers for extruded-dielectric cables than pipe-type cables.

After evaluating the two options, CEPCI chose extruded-dielectric, cross-linked polyethylene (XLPE) insulated cables. The cable design is conventional, as in many projects. The principal design decision was the cable sheath material. The ducts would be filled with water, and the cables must operate for many decades under a hydrostatic head of more than 60 ft (18 m). Although laminate shields have a good operating history for land installations, CEPCI decided to specify the the sheath with proven reliability, lead, as commonly used for submarine cable applications.

The added weight of the lead sheath was a major concern in cable pulling, but calculations showed it was acceptable for the 3400-ft length. Placing a temperature-monitoring fiber-optic cable under the lead sheath was considered, but CEPCI determined a separate multifiber cable in the duct was preferable to permit multiple single-mode communications fibers as well as a few multimode fibers for distributed temperature sensing. This makes it possible to replace the fiber-optic cable in the future.

CEPCI considered installing and terminating a fourth cable for quick connection if one of the primary cables failed, as has been done on other river-crossing cable circuits. However, since alternate paths existed to feed Wadmalaw and Johns Islands for the time it would take to obtain new cable, the utility opted to install a fourth duct that could be used for replacement cable if a failure occurred.

The cable and terminations were supplied by LS Cable. The cable was delivered to the port of Charleston on three individual reels, trucked to the local co-op’s storage yard and brought to the installation site on New River Electrical’s special reel trailers when needed for installation. Cable installation went smoothly, due in part to the liberal application of lubricant.

The area from the end of the HDD ducts to the base of the termination pole was directly buried, and an S-bend was placed in the excavation to allow termination replacement if needed, without having to install a splice. The entire area was covered with a weak-mix concrete for mechanical protection.

CEPCI had its overhead-line tower supplier design and supply the transition monopoles at each end of the line. The cables were securely clamped to the pole prior to placement of a steel shroud, and terminations were made at final pole-arm height using manlifts. The 138-kV class terminations were chosen because of the proximity to saltwater.

The commissioning tests consisted of jacket integrity tests to verify there was no cable damage during installation, partial discharge measurements at 1.7 times operating voltage to verify there were no discharges that could lead to eventual electrical failure and a 24-hr ac soak test at line voltage, with one end open. All tests were passed successfully, and the transmission line was placed into service in June 2018 on Johns Island and Wadmalaw Island.

Jimmy Tindal ([email protected])is director of transmission design and construction at Central Electric Power Cooperative Inc. With over 30 years of experience in transmission design and construction, this was the first HDD XLPE cable installation project for Tindal and the utility.

Jay Williams ([email protected]) is the founder and executive engineer at Power Delivery Consultants Inc. He has specialized in transmission cable systems since joining Consolidated Edison Inc. in 1965. Williams has been a project engineer for more than a dozen trenchless installations for both pipe-type and extruded-

dielectric cables as well as a great many research projects and other applications of transmission cables for conventional and novel installations.

Rachel Mosier ([email protected]) is the principal engineer at Power Delivery Consultants Inc. With over 25 years in the utility industry, she has extensive experience with extruded-dielectric transmission cable systems through 500 kV. She is active with national and international technical committees.

Dennis Doherty ([email protected]) is a senior principal professional with Kleinfelder Inc. He served as the project engineer for Haley and Aldrich Inc. on the CEPCI HDD project. For more than 20 years, Doherty has specialized in installing high-voltage cables underground using various trenchless technology methods, including horizontal directional drilling. In collaboration with Power Delivery Consultants Inc., he also coauthored the Electric Power Research Institute’s Quality Guidelines for Grouting Procedures for Large Casings Used for Transmission Cable Systems.

Abhinav Huli ([email protected]) is trenchless practice leader at Haley & Aldrich, Inc. He specializes in the technical design of new utility conduit installation using trenchless technological applications and has over a decade of industry experience working on trenchless project from conception to construction. He has worked on numerous large scale microtunnel and Horizontal Directional Drilling (HDD) projects along the east coast with most of the large HDD projects being 6,000+ft drills.

For More Information

H&A | www.hayleyaldrich.com

LS Cable & System | www.lscusa.com

Mears Group | http://www.mears.net

New River Electrical | www.newriverelectrical.com

PDC | www.pdc-cables.com

About the Author

Jay Williams

Jay Williams is the founder and executive engineer at Power Delivery Consultants Inc. He has specialized in transmission cable systems since joining Consolidated Edison Inc. in 1965. Williams has been a project engineer for more than a dozen trenchless installations for both pipe-type and extruded-dielectric cables as well as a great many research projects and other applications of transmission cables for conventional and novel installations.