Eversource Innovates with Fusesaver Pilot

Eversource Energy recently installed Siemens’ Fusesavers in its Connecticut service territory. The installation started as a pilot project to help the utility meet the reliability goals of its system resiliency program.

Like other electric utilities across the U.S., Eversource is upgrading its electrical distribution infrastructure to better withstand extreme weather-related events and to improve customer reliability. Improving service reliability with the deployment of single-pole switching devices and new low-cost fault-interrupting Fusesavers will provide the utility immediate reliability improvements.

Fault-Interrupting Functionality

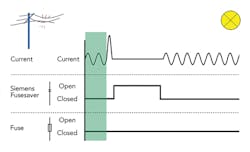

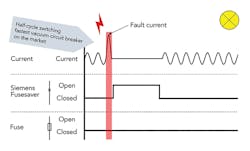

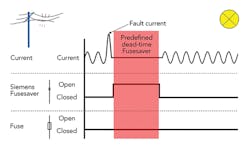

The Fusesaver is a self-powered, electronically controlled single-phase fault-interrupting device that works in partnership with a fuse to protect a lateral line from temporary faults. It is capable of detecting, opening and clearing a fault in a half cycle, which is less time than it takes the fuse to melt. It will interrupt an overcurrent condition and then reclose automatically to re-energize a line and determine whether the fault was temporary. It is estimated more than 70% of faults are temporary.

After reclosing, the Fusesaver will remain closed, even if the fault is permanent, then the associated fuse will open to interrupt and isolate the fault. If the fault was temporary and the reclose successful, the Fusesaver will reset itself in preparation for any future disturbances. The Fusesaver will operate similar to hydraulic reclosers, currently used on the Eversource system.

Eversource identified 32 locations throughout its Connecticut service territory for single-phase and three-phase installations on 13 distribution circuits. In conjunction with Siemens and Burns & McDonnell, Eversource also produced a T&D How video focusing on the installation of a single-phase Fusesaver. The video demonstrates the pole construction and installation in accordance with Eversource standards.

Pilot Implementation

Eversource distribution standards brought several cross-functional disciplines together to implement this new reliability-transforming design. The T&D standards group provided a construction standard, an engineering manual (DSEM) describing the unit and its capability, an installation video and a training webinar. Line crews, the test department and other supporting field operational personnel received this training. The Eversource test group also had a two-day training seminar on the Siemens Connect software used to program and interrogate the Fusesavers through a wireless USB connection.

The Eversource construction standard details how to construct a pole with a Fusesaver. The Fusesaver mounting will be on the load side of the fuse with the remote control unit (RCU) cabinet mounted on the pole. This construction standard covers single-phase and three-phase construction.

Other areas of importance covered in the construction standard’s notes are minimum primary cable connections and grounding requirements. Wedge tap connectors are used to connect to the primary lines, and compression lug connectors are used to connect to the Fus-saver. Fusing for the 120-Vac power supply is located inside the RCU cabinet. For three-phase applications, only one RCU cabinet is needed. The RCU cabinet is bonded to the pole ground and is to be installed 5 ft (1.5 m) above finished grade.

The Eversource standards group also provided installation training to the individual line crews with a hands-on component. The three modes of operation for the Fusesaver — manual, Wi-Fi, and supervisory control and data acquisition (SCADA) — were emphasized because of the addition of wireless operation. A Fusesaver guide for field engineers also was created by the utility’s resiliency group, with input from the protection and control group. The purpose of the guide is to assist field engineering to plan and locate viable candidate sites for Fusesaver installations.

Some site restrictions are as follows:

• Stepdown transformers downstream

• Single-phase recloser locations

• Fault current levels.

Other areas for consideration include the SCADA integration of Fusesavers on existing SCADA system, geographic information system/outage management system (GIS/OMS) integration, screens for system operator and nomenclature for mapping.

Eversource traditionally uses radio broadcast base station sites in its Connecticut service territory for recloser backhaul of SCADA points to the systems operation center. However, in the Fusesaver application, wireless mobile 4G gateways using the input/output model option were used to backhaul SCADA points to the systems operation center in Berlin, Connecticut, as a result of space constraints in the RCU cabinets. The relevant areas of expertise needed to be consulted to help integrate the Fusesavers into the existing GIS/OMS infrastructure with an eye toward the future distribution management system.

Leveraging Features

One additional safety feature for line crews is the 60-second hit-and-run function of the Fusesaver. Linemen are able to close in the Fusesaver manually with the red lever on the communications module, which is an optional feature located on the bottom of the unit. Line crews can lower the bucket to a safe distance away from the Fusesaver when switching back in a circuit. The Connect software also has an event log that stores event history in permanent memory. The memory can be downloaded for analysis of events on the distribution system. The event is time-stamped, which is helpful in analyzing circuit outages.

Lessons Learned

New product introduction into the distribution system has a huge ripple effect across the organization. Much of the operational organization is affected and needs to be kept updated on the smart grid technologies integrated onto the distribution system. A distribution engineer’s job is not only to innovate but also to inform. A significant part of a standard engineer’s job is to help educate the field about new product introductions being implemented. Listening to the field organization on suggested enhancements and modifications also goes a long way in acceptance of a new product.

The time invested upfront rolling out the Fusesaver and training the workforce will directly correlate to ease with and adaptation to the new technology. The dividends of upfront communicating and training will translate into acceptance and success of the new product. The bottom line is one needs to communicate often and early for new product developments and designs. The successful deployment of Fusesavers in Eversource’s Connecticut service territory has paved the way for installation in its western Massachusetts service territory. Ten Fusesaver installations with SCADA capabilities are planned for later in 2016.

As more installations are completed, these smart grid technologies will help to deliver the resiliency and system reliability expected from both regulators and customers.

Acknowledgement

The author would like to acknowledge the following individuals for their technical support throughout the pilot: Carl Peterson, manager T&D Eversource Energy; Steven Pell, product manager for Siemens Industry Inc.; and Christopher DeSanctis, president D&D Electrical Sales Inc. Special thanks goes to James Beatty, Eversource Energy’s supervisor of electric field operations New London. Finally, thanks to the dedicated line crew that helped to make the Fusesaver installation video possible: Ernesto Punzalan, Jeremy Rose and Scott Herman.

Timothy J. Callahan received BSEE and MBA degrees from the University of Hartford. He has more than 26 years of experience in the electric utility industry and is an active member of the IEEE Power & Energy Society’s Connecticut chapter. Callahan is a distribution standards senior engineer with Eversource Energy. His main focus is developing and implementing standards for distribution automation (smart grid). He also is developing and implementing standards for leased line, power line carrier, unlicensed spread spectrum radio and fiber-optic distributed generation transfer trip schemes.

Fusesaver Guide

The Fusesaver guide for distribution field engineers was created to help engineers integrate the Fusesaver into the Eversource distribution system. The guide provides criteria to choose locations for installation. A holistic approach is used to help maximize the benefit of the Fusesaver and to prioritize locations to get the biggest bang for the buck.

The Fusesaver has a fault current withstand limit of 4000 A and is available in 100-A and 200-A models. To streamline the process, Eversource decided to standardize on the 200-A model because it provides a greater fuse coordination range than the 100-A model, and the minimum line current needed for operation of the device is 0.5 A and 1 A, respectively. The 200-A Fusesaver coordinates with a range of K-class and T-class fuses (from 10 A to 100 A).

Because the device is connected to the Eversource supervisory control and data acquisition (SCADA) system, data about an event, device reliability and availability, and load profile can be accessed from the database through SCADA. This data can be helpful for distribution engineers to monitor distribution circuits effectively and efficiently. For example, the event database can provide a record of faults and protection operations to help determine line reliability. It also can confirm the Fusesaver is operating as expected, help to diagnose faults and determine how many fuses have been saved by the Fusesaver.

The access event database can assist distribution engineers with data analytics. The Fusesaver’s event database saves up to 3000 events, such as a protection trip or line current, in the order of occurrences.

The Fusesaver can be installed on single-phase or three-phase side taps. Eversource decided the device would not be installed to protect stepdown transformers to avoid exposing the stepdown transformer to fault current twice during a permanent fault, first when the Fusesaver operates and second when the fuse operates.

Because of coordination issues, the Fusesaver also should not be installed upstream or downstream from an existing single-phase recloser. It is critical that the distribution engineer have a good understanding of the loading for prospective Fusesaver installation locations. Nomenclature for Fusesavers also is important for the geographic information system/outage management system and SCADA systems. As an example, in Eversource’s Connecticut service territory, a single-phase Fusesaver is designated with the circuit number and device designation, such as 12A3-1601F.