From Local Intelligence to System Intelligence

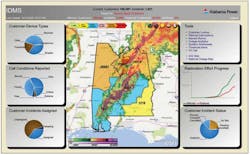

Two of the most revolutionary advancements Alabama Power Co. has seen in distribution came with the implementation of both Fault Isolation and Service Restoration (FISR) as well as Fault Location (FL) in its Advanced Distribution Management System (ADMS). These two advanced applications have changed not only the way the utility views automated devices, but also how it uses them. With utilities seeking ways to make the best use of automated devices, using FISR and FL in an integrated ADMS is a powerful way to make a positive impact on their business and their customers.

FISR And FL

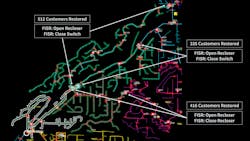

FISR is a model-based application that analyzes emergent outages dynamically in the system to develop restoration plans, check them for potential issues using real-time power flow, and implement the switching steps through Supervisory Control and Data Acquisition (SCADA) controls. Although FISR is a form of Fault Location Isolation and Service Restoration (FLISR), there is one key difference between the two. While FLISR requires the use of FL halos to dictate where to sectionalize lines, FISR relies on SCADA fault targets.

Although Alabama Power’s ADMS solution from GE Digital can be configured to run FLISR or FISR, the utility is careful to specify it uses FISR, with FL running separately. FISR can run in several different modes — from closed-loop mode, which automatically uses automated devices to restore customers, to advisory mode, which provides recommended restoration plans using all available switching devices on the system.

Alabama Power is no stranger to local schemes, having deployed many different setups over the years. When compared to these time- and maintenance-intensive traditional schemes, FISR has some attractive qualities.

Because FISR resides in the ADMS itself, no special relay logic is required for field devices. With this bird’s-eye view in ADMS, FISR also can create dynamic restoration plans even when the system is abnormal. Because FISR sends controls through SCADA, it does not require peer-to-peer communication between devices or rely on specific device manufacturers. Further, unlike traditional centralized schemes, FISR uses the as-switched ADMS model, so there is no separate model to build and maintain. These qualities quickly set FISR apart from traditional technology, making it a good fit for Alabama Power.

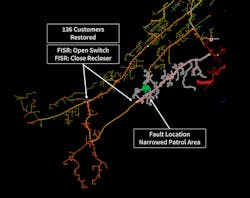

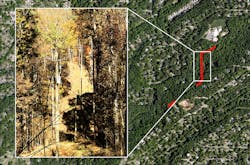

The FL application uses SCADA fault current magnitudes and the as-switched distribution system impedance model to calculate estimated fault locations. These locations are presented graphically as halos painted on the ADMS geographic, assisting operators and crews in patrolling. Distribution faults can be difficult to patrol because of the rear-lot construction of lines and limited nighttime visibility. By automatically calculating and painting halos, FL can significantly reduce the time it takes to patrol outages, leading to decreased outage time for customers.

The fault current magnitudes FL uses are reported by SCADA from substation feeder relays, line recloser relays and fault indicators. The configurable halos painted on the ADMS geographic are ±5% of the calculated fault location and remain on the geographic while the lines are deenergized.

Deployment Strategy

Alabama Power began FISR deployments following a small pilot in Birmingham, Alabama, U.S., in 2018. To ensure realistic power flow simulations of proposed FISR plans, Alabama Power worked on improving feeder models before deploying FISR. These model improvement efforts included replacing bad SCADA sensors and field checking locations with suspect modeling.

Several reports were written to flag suspect data for end users to investigate. This is a departure from the way model data traditionally has been used. From SCADA measurements to Geographic Information System (GIS) conductor sizes, the model data now has real-time impacts on system restoration. FISR was deployed to approximately 60 substations every six weeks, which allowed time for this model improvement process to take place.

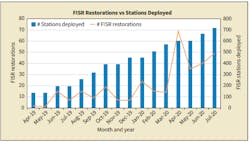

After the pilot concluded, FISR deployment was completed in 18 months for all system substations and feeders that were appropriate candidates for the technology. While there are particular customer conditions that make a substation or feeder ineligible for FISR, Alabama Power has been able to deploy it successfully to 98% of its customer base. The deployment area included more than 715 substations, 1,890 feeders and approximately 5,300 SCADA devices. In addition, more than 220 local schemes were disabled, with the devices being handed over to FISR. The more SCADA line devices that exist on a substation, the more opportunities in which FISR can assist during outages.

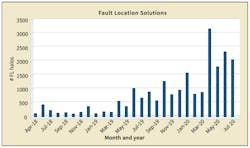

FL was deployed with distribution power flow in early 2018. Starting in 2019, Alabama Power began installing additional fault indicators just under the feeder breakers where no relay fault targets existed. Placing fault indicators at the feeder heads enabled FL to have visibility of all faults on the feeder. These installations proved much more cost-effective than upgrading older relays, while also giving end users engineering access to analyze fault data.

Real Results

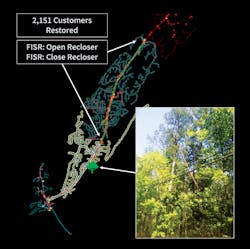

When compared to local schemes that require events to be downloaded and evaluated manually, FISR greatly simplifies tracking results because it exists in the ADMS, which archives every evaluation and restoration. Through Aug. 1, 2020, FISR has restored customers 332 times successfully across Alabama Power’s service territory, avoiding approximately 42.8 million customer minutes of interruption (CMI). The average FISR plan restores 509 customers and 3,867 kWh while avoiding 129,852 CMI.

When evaluating FISR’s success, what especially caught Alabama Power’s attention is 86% of the FISR plans used at least one non-scheme device. In this case, the term “non-scheme device” refers to a device that was not a member of the more than 220 decommissioned local schemes and handed to FISR. In other words, 86% of the time FISR was able to restore more customers than the decommissioned schemes would have.

Perhaps more impressively, 68% of the FISR plans used only non-scheme devices, meaning these restorations were only possible automatically with FISR. These statistics highlight the true potential of FISR — mobilizing automated devices to participate in restorations in which they were not able to previously.

As a case study on FISR’s effectiveness, a major storm hit the Alabama Power service territory on April 12, 2020, affecting more than 312,000 customers, or over 20% of the utility’s customer base. There were 23 confirmed tornadoes, which resulted in more than 2,000 spans of wire down and 460 broken poles.

During this storm, FISR implemented 31 restoration plans across the service territory, avoiding an estimated 11.8 million CMI. These FISR restorations had a particularly positive impact during the storm because they helped customers avoid outages during the abnormally prolonged restoration process. While this was a significant storm, it was only one of four major storms to hit Alabama Power that month. In April 2020 alone, FISR implemented 71 successful restorations.

A major concern for utilities in 2020 is the safety of their employees in the wake of COVID-19. Since March 16, 2020, Alabama Power has been implementing social distancing and other precautions on-site to protect its employees. To minimize the impact on efficiency when working storms and outages, ADMS advanced applications are helping to fill the gap to maintain reliable service to customers.

Of the 206 FISR plans implemented from March 16 through Aug. 1, 2020, 82 plans restored over 60% of the impacted customers, 128 plans avoided an estimated 50,000-plus CMI each, and 26 plans involved four or more switching steps. Each time FISR can restore customers and avoid outages that last for several hours, it has a positive impact on Alabama Power’s customers. In total, these FISR restorations since March 16 helped Alabama Power to avoid an estimated 26.9 million CMI.

Although the FISR benefit of avoiding outages certainly is positive for the utility, avoiding outages is much more impactful for society. Per the U.S. Department of Energy’s interruption cost estimate (ICE) tool, all FISR restorations combined avoided an estimated US$82.5 million for Alabama Power’s customers. While a tangential financial benefit, there are very real impacts on business owners who must close early for the day or send employees home early as a result of an outage. Other benefits include time saved on not maintaining local schemes, improved employee safety by not having to switch lines manually and reduced employee time spent in the field.

Through Aug. 1, 2020, FL has proposed potential fault locations over 21,000 times. Approximately 17% of these FL halos were for sustained interruptions, with the distribution control centers reporting a 90% FL accuracy rate. This high level of accuracy has encouraged operators to use fault halos whenever they are available, to the point where first responders take the initiative to ask operators what FL says before they begin patrolling an outage. On average, FL halos painted on the real-time ADMS geographic reduce the patrol distance by 66%, or 1.83 miles (2.94 km), which the distribution control centers confirm has reduced patrol time for outages. In total, FL halos painted on the real-time ADMS geographic have reduced the distance crews must patrol by roughly 6,655 miles (10,710 km).

In addition to operators in the control center, users evaluating in the field also have access to FL results in the form of a report that overlays the FL results onto satellite images and road maps. End users no longer need to run fault simulations on engineering software to take advantage of this data. Although it typically does not generate the same excitement as FISR, FL is having a significant impact on reducing outage times for Alabama Power’s customer base.

Lessons Learned

It is difficult to overstate how revolutionary FISR and FL have been to Alabama Power’s approach to distribution. Many of the utility’s modeling techniques, maintenance procedures and switching procedures had to be reevaluated to consider how FISR would behave or use the data.

One lesson was the value of model integrity, especially in maintaining data after the initial model improvement. Because the distribution system is dynamic, changes are being made every day. When storms occur, it is difficult to keep track of all the changes made by line crews trying to get the lights back on as quickly and safely as possible. To combat this model drift, several reports were built that actively query GIS and ADMS models to flag suspected issues for investigation. Additionally, the philosophy that the districts know their areas best and should maintain FISR was adopted.

A surprising ally in maintaining models was distribution power flow, another advanced application in ADMS that was enabled at the same time as FL in early 2018. Distribution power flow quickly can identify where potential modeling issues exist that need to be investigated. Case in point, there have been quite a few times where distribution power flow correctly identified not only modeling issues but also system issues.

Another lesson was reinforcing the importance of including end users in all stages of development and testing. Involving users to help shape the look and feel of these advanced applications led to a positive reception when these tools were deployed to ADMS. The end users also identified potential issues and scenarios that could be addressed before the tools were deployed. They helped to champion the value of the tools, train others and answer questions.

On the vendor side, Alabama Power participates in GE Digital’s working groups with other customers to ensure the applications continue to evolve positively.

Next Steps

The transformative success seen in just the first 24 months of advanced applications in the ADMS has changed Alabama Power’s vision of distribution. FISR loss-of-voltage triggering is scheduled to be deployed within the year, where restoration plans will be implemented automatically during transmission outages. Another effort underway is the implementation of a Distributed Energy Resource Management System (DERMS) in GE Digital’s ADMS, so renewable generation can be integrated successfully with the distribution system and FISR can keep better track of these loads during plan evaluation.

ADMS, FISR and FL have changed the Alabama Power’s distribution approach, from the field to the office. It still has challenges to overcome, but the benefits realized by the utility’s customers and employees as well as Alabama businesses have been nothing short of impressive. There is so much more to come.

Matthew Leak is a senior ADMS Advanced Applications engineer for Alabama Power, providing technical leadership and support for Distribution Power Flow, Fault Location, and FISR. He earned his BSEE and is a professional engineer licensed in Florida. He transferred to Alabama Power in 2017 from Gulf Power where he served in various technical roles in distribution, including Reliability, Distribution SCADA, and Protection & Control.

About the Author

Matthew Leak

Matthew Leak ([email protected]) is a senior ADMS Advanced Applications engineer for Alabama Power, providing technical leadership and support for Distribution Power Flow, Fault Location, and FISR. He earned his BSEE and is a professional engineer licensed in Florida. He transferred to Alabama Power in 2017 from Gulf Power where he served in various technical roles in distribution, including Reliability, Distribution SCADA, and Protection & Control.