Asset Security Strategy Addresses Fire Protection

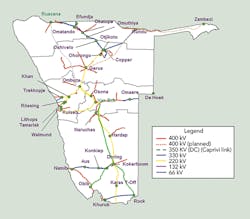

The Namibian Power Corp. (NamPower) is the sole transmission system operator in Namibia, with a transmission system comprising 11,000 km (6,835 miles) of overhead transmission lines ranging from 11 kV to 400 kV. The rapid expansion in developing countries, like Namibia, has resulted in an increase in energy consumption, which has created a snowball effect on power generation, electricity transmission and the entire electricity network.

As a result, NamPower is challenged by the ever-increasing demand for energy and need for a reliable electricity network. The utility also faces challenges in procuring major assets, such as long lead times associated with manufacturing, increasing operating costs and increased loading of existing system assets.

Namibia is a southern Africa country that borders the Atlantic Ocean to the west and shares borders with Angola and Zambia to the north, Botswana to the east and South Africa to the south. Namibia has an area of 825,418 sq km (318,694 sq miles) and a population of approximately 2.324 million with a population density of some 2.8 people/sq km (7.25 people/sq mile), making it one of the most sparsely populated countries in Africa and the world.

NamPower’s long-term vision is to be a leading energy utility in Africa. It will achieve this by continuously improving its customer service, technological innovation and employees through development. To reach this goal, NamPower needed to establish a strategic and operational basis to satisfy the energy needs and expectations of its customers and stakeholders. To this end, the utility put in place an asset management strategic plan and policy that cascades from the utility’s overarching strategic plan, which aims to ensure all system assets operate at the highest levels of reliability and availability.

As a result, asset management practices and approaches for critical network assets need to be continuously optimized and streamlined to improve and overcome the obstacles posed by the network configuration that is still prevalent on critical network substations.

Electric Protection

Namibia is largely an importer of electrical energy, so where possible, the Namibian backbone of transmission lines and connecting grid substations are planned and constructed with n-1 system security contingency. To improve the availability and reliability of these assets, specifically grid transformers and reactors, NamPower has equipped these assets with specialized electrical and mechanical protection. One such innovation is a mechanical protector, the Sergi transformer protector.

NamPower employs and adheres to the Namibian Grid Code requirements as well as protection protocols as specified in IEC and IEEE standards. These standards are a combination of an integrated system of protection protocols that combine to create a complete system for each type of asset. Primarily, these systems are of a redundant functionally equivalent protection system (FEPS) type. Each scheme provides redundancy by design, with at least two intelligent electronic devices (IEDs) that act either as main 1 and main 2 or as main and backup to increase protection function security for each protected bay.

Although the capital investment is essentially doubled as a result of the duplication of IEDs installed in the scheme, the trade-offs are negligible when considering the benefits made in terms of the robustness of the scheme and increased security of supply to customers.

Transformer Fire Protection

NamPower began researching alternative transformer fire protection systems because of the criticality of generation transformers located underground at the Ruacana Hydro Power Plant that supply the utility’s system and the ineffectiveness of a normal water-spray system during an actual transformer oil-fueled fire.

The rupture disc transformer protector (TP) technology, patented worldwide by Sergi in 1999, was identified as the most feasible and preferred mechanical technology to enhance the prevention of a total catastrophic loss of a transformer and even the power plant. The TP is a transformer explosion- and fire-prevention technology based on a direct mechanical response to a change in the tank dynamic pressure because of an electrical fault. As a result of nitrogen being injected into the transformer tank, the TP not only offers fire prevention, it also is a fire-extinguishing system

In 2000, NamPower procured and installed three first-generation TP systems on the three Ruacana 330/11-kV, 80-MVA generator transformers. In 2002, NamPower installed an additional two units on a 400-kV, 100-MVAR reactor and a 220/66-kV, 160-MVA transmission transformer. Considering the increasing transformer lead times, insurance requirements and large capital investment required, NamPower’s transmission management group made the decision that all indoor substations, strategic network transformers and reactors ≥40 MVA or with a high voltage of ≥220 kV should have a TP protection system.

The rationale in support of this decision was that by optimizing and standardizing the transformer mechanical protection, the damage resulting from an electrical fault could be contained more easily and corrected because a complete transformer fire poses a major fire risk to all the surrounding equipment. As a result, from 2003 to date, 47 strategic network and indoor transformers and reactors have been equipped with TP systems.

TP Principles and Installation

In the event of an electrical fault within the transformer, the TP is activated within milliseconds by the first dynamic pressure peak of the shock wave created by the electrical arc ignition before the static pressure increases. The insulating oil-gas mixture is evacuated to an oil-gas separation tank and the transformer conservator shutter closes.

An air isolation shutter prevents oxygen from coming into contact with the explosive, flammable oil-gas mixture, which opens the air isolation shutter. The oil-gas mixture is channeled to a safe remote area or, alternatively, outside the transformer enclosure. Nitrogen injection is activated either manually or automatically when the control panel receives an indication that the depressurization set rupture discs have operated. The injection of an inert gas (nitrogen) ends the generation of the explosive gasses channeled to protect maintenance personnel from harm when opening the transformer tank following the incident. Nitrogen injection continues for some 45 minutes to ensure cooling of the insulating oil and end explosive gas production.

The transformer protection system can be adapted easily for installation on new or existing transformers with ratings of 1,000 MVA and above. Retrofitting the TP to existing transformers and reactors can be completed without the need to drill or machine the transformer tank with maintenance flanges or covers being modified for TP fitment. The standard oil sampling and filtering valves at the bottom of the transformer tank are adapted to provide the facility required for nitrogen injection. A nitrogen cabinet must be located in close proximity of the transformer, but the control panel can be positioned in the control and relay room.

Cost-Benefit

Many insurers and risk managers consider transformers one of the most critical pieces of plant equipment because of the large quantity of oil contained that is in constant contact with high-voltage elements as well as the high capital cost of replacement.

Today, utilities employ common strategies that include increased equipment usage, delayed capital expenditures and reduced maintenance expenses. In developing countries, it is common for electricity consumption to increase substantially on a yearly basis. This often results in aging transformers being overloaded, increasing the risk of catastrophic failures.

When such catastrophic failures occur, the damage and financial consequences for the utility and the community affected are often considerable. Cost incurred does not always only include production or distribution loss, it also can include the cost of replacement of the damaged transformer and equipment, installation of new equipment, cleanup and repair, commissioning, environmental damage and penalties.

One of NamPower’s major considerations for installation of the TP’s are based on the following calculation:

FB = CoPI/(CoCF – CoR),

where FB = financial benefit, CoPI = cost of TP procurement and installation, CoCF = cost of catastrophic failure (worst-case scenario), and CoR = cost of transformer replacement.

If the financial benefit is ≤4%, installation of the TP is considered. However, if it is higher than 4%, alternative options are investigated. The decision to install the Sergi TP on all indoor substation and strategic network transformers, as well as reactors ≥40 MVA or with a high voltage of ≥220 kV, was based on the application of this methodology.

On average, the maintenance cost for the TP is between 5% to 7% per year of the system procurement cost. With proper resource planning, the system is relatively maintenance free with major replacements in 5-year and 10-year cycles. At NamPower, TP components also have replacement frequencies:

• Electrical actuators are replaced every two years.

• Rupture discs are replaced every 10 years.

• Conservator shutters are replaced every five years.

• Shock absorbers are replaced every 10 years.

A Forward Looking Approach

As part of its strategic and risk management considerations, NamPower decided to equip all indoor substation and strategic network transformers and reactors with Sergi TP systems. To date, NamPower has not experience any catastrophic failures that have required activation of the protection systems. However, ample accounts do exist of successful TP operations.

For NamPower, the main benefit of the TP is the risk mitigation on critical and capital-intensive equipment. Installation of the TP is expensive; therefore, the utility used a detail cost-benefit analysis as well as criticality profiling of substations and equipment as decision criteria for use of the TP protection. Also, there is not a local southern African supplier, so all equipment and spares are sourced from France or the U.S. Because of logistical delays and international procurement regulations, critical spare planning and holding have to be incorporated in long-term planning and budgets.

Acknowledgement

The author wishes to acknowledge the support and assistance provided by Frank Engelbrecht, Chris Viljoen, Benjamin Noël and Ben Landis in the preparation of this article.

Gerhard Myburgh ([email protected]) holds a BTech degree in mechanical engineering and a MSC degree in technology management. He has been employed by the Namibia Power Corp. since 2004, and has served as section head for the condition monitoring, computerized maintenance management system and multidisciplinary projects with the asset maintenance division of the transmission business unit.