The Tehran Regional Electric Co. (TREC) is the largest utility in Iran, responsible for 20%, or approximately 12,000 MW, of the country’s installed generating capacity. With a population of more than 12 million, Tehran, the capital of Iran, has developed rapidly during the past two decades, with multistory buildings increasing the electricity demand required to supply residential and industrial customers.

Some of TREC’s existing 400-kV and 230-kV transmission lines, now considered distribution lines, were constructed originally beyond the city limits but are now within the city boundary as a result of the growth. New infrastructure under construction, including highways and bridges, has resulted in the need to move sections of the existing 230-kV overhead transmission line system underground. Because it had experience providing similar engineering services both in Tehran and other Iranian cities, Namdaran Transmission System Co. (NTS) was awarded the contract to move the 230-kV double-circuit transmission line underground.

Initially, it appeared to be a straightforward job, excavating trenches and channels to bury the underground cables, followed by dismantling the overhead lines. However, the execution of such a project in a highly populated area subject to heavy traffic congestion and many existing underground utilities, such as electricity and telecommunications cables, gas pipelines and water pipes, presented a major obstacle. In view of the urgent need for this 230-kV circuit, NTS decided to replace a section of the existing 230-kV double-circuit overhead line with two 230-kV underground cables installed in a cable tunnel under the city center.

Underground Cables

The 230-kV transmission line section to be replaced by underground cable was located between the Ozgol substation and Qeytarich substation, two major substations in the city center that supply energy to the very important areas in north and northeast Tehran. The 230-kV transmission line to be replaced is 7.5 km (4.6 miles) in length. The design length for the underground cable route was 6.2 km (3.8 miles).

NTS accepted responsibility for all the electrical services, but LAR Consulting Engineers was engaged for the design and supervision of the civil works. The project had four critical points:

- Construction of a bridge was a prerequisite before dismantling the existing 230-kV overhead line. The design, supply of the underground cable, and accessories and construction of an underground cable tunnel, and installation of the cable had to be completed within six months.

- Construction of the concrete cable tunnel was designed for a depth of 10 m (33 ft) beneath the heavily populated area in downtown Tehran.

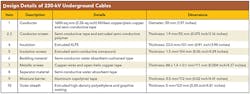

- Underground cables specified by NTS for the 230-kV cables were single-core, cross-linked polyethylene (XLPE)-insulated copper conductor cables with a cross section of 1600 sq mm (2.28 sq inches).

- Cable accessories, which included prefabricated one-piece slip-on joints and link boxes, were supplied by Pfisterer, but the 230-kV cable and other materials were provided locally. Pfisterer was selected because it had previously supplied materials to TREC.

Cable Tunnel Construction

The project’s six-month timetable for completion proved to be a demanding challenge for the major civil works and the manufacturer of the 230-kV cables and accessories.

Four contractors were awarded contracts for the civil works associated with construction of the cable tunnel. Coordination between the four contractors was important because of the urgency to complete the tunnel. All agreed if one contractor was unable to finish its responsibilities, the remaining contractors that had made greater progress could capture the increased work to finish the construction works on time.

As the proposed route was beneath the city center, heavy traffic prevented the use of tunnel-boring machinery. Hence, excavation work was undertaken with minimal use of specialized equipment. During construction, a water ingress problem emerged, so it was necessary for two sections of the tunnel to be sealed by specially insulated sheets, which resulted in changing the route of the water.

When tunnel construction was 50% complete, more contractors were employed to start installing the cable supports.

Initially, TERC planned to purchase one 230-kV cable from a Korean manufacturer and the second 230-kV cable from an Iranian manufacturer, Abhar Cable. However, Abhar Cable was able to promise delivery of both cables on time and, therefore, was awarded the contract for both the 230-kV cables.

Abhar Cable operated its factories 24 hours a day to manufacture and deliver the cables to the site on time. During the manufacturing process, appointed consultants witnessed the specified routine and sample approval tests. The specified cable also had type test certification from the KEMA high-voltage laboratory in The Netherlands.

Two Iranian contractors were awarded the contract to install and joint the 230-kV cables. This contract also included the installation and jointing of four 63-kV cables, optical ground wire, communications and traffic control cables. It was agreed Pfisterer would provide two supervisors throughout the jointing process, but this did not materialize. Only one supervisor attended the jointing for a short period, leaving the trained and certified technical Iranian jointers to complete the jointing without supervision.

Cable Commissioning

The complete installation of the cable tunnel was commissioned and energized within the six-month timetable. The work to dismantle the existing 230-kV transmission line was completed two weeks earlier than estimated and without the need to disrupt the city center traffic.

More Underground Tunnels

Underground transmission systems and distribution networks seem to be the inevitable choice for mega-sized cities. Although a number of technical parameters are involved in the design and construction of such a project, these can be addressed. However, there are several other problems and issues that require consideration, for example, the other utility networks installed underground and the density of traffic. On this particular project, traffic density prevented civil works from being undertaken during a number of hours each day. Therefore, TREC was pleased to complete this project within the specified six-month schedule, which proved to be a record for a project of this kind in Iran and other countries.

It appears planning underground tunnels has significant benefits for many other urban infrastructures such as telecommunications, gas, water and wastewater systems. The multi-purpose tunnel offers a solution for mega-sized cities in the future. Currently, a multipurpose tunnel is under consideration in Tehran, and the Iranian cities of Esfahan, Tabriz and Ahwaz also are planning the construction of multipurpose tunnels, one of which is in the tendering stage.

NTS is planning to replace many of the existing overhead lines with underground cables in Tehran and possibly in several other major cities in Iran in the next five years.

Acknowledgement

The author wishes to thank TREC staff, including Managing Director S.Z. Hosseini and his deputies Mr. Afsari and Mr. Fallah, as well as Mr. Khodabakhsh; the municipality of Tehran, including Dr. Ghalibaf, the mayor of Tehran, and his deputies Dr. M. Hosseini and Mr. Emam, for their valuable support; and LAR Consulting Engineers for their kind cooperation.

Mohsen Pourrafie Arabani is the managing director of Namdaran Transmission System Co. He holds a BSEE degree from Sharif Technical University, and master’s and Ph.D. degrees in power systems from the Polytechnic University of Bucharest. Arabani worked for Moshanir Power Engineering Consultants with the Iran Ministry of Energy for more than 30 years in various roles as manager of the overhead lines, substations, research and development, and overseas departments. In parallel, Arabani was a lecturer at the Polytechnic University of Tehran, where he established the CIGRE branch in Iran. He is secretary of the CIGRE National Committee and a senior member of IEEE and the Iranian Association of Electrical and Electronics Engineers.