Monitoring of Overhead Transmission Systems Using Embedded Optical Sensors

Severe mechanical failures of transmission systems can occur in-service due to various extreme situations. Therefore, it is important to have the ability to monitor the grid for excessive mechanical and environmental loadings to identify and mitigate potential catastrophic failures of vital components. In this work we show how this can be accomplished, for example, for current and next generation conductors.

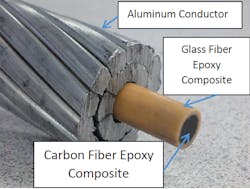

Composite based High-Temperature Low-Sag (HTLS) overhead transmission lines (Figure 2) were developed in response to the world’s increasing consumption of electricity. Designed to operate in harsh and highly dynamic environments with limited sagging, these conductors are expected to last for many decades. A multitude of mechanical and environmental loading conditions can occur in-service or during installation, and include excessive bending, aeolian vibrations, galloping, ice loading and shedding, impact from falling objects, hot spots, aging, galvanic corrosion, and others [2-6]. These events could seriously compromise the structural integrity of the conductors leading to their in-service failures and severe disruptions in power delivery.

At present, monitoring transmission lines for mechanical problems caused by excessive installation or in-service loads is very difficult or even impossible. A new ability to monitor the structural response of HTLS conductors would be especially beneficial to reduce costs associated with maintenance and inspection, as well as improve the capability to perform life predictions of modern transmission systems. The National Science Foundation Industry/University Cooperative Research Center for Novel High Voltage/Temperature Materials and Structures (HVT Center) at the University of Denver has been developing techniques to monitor overhead lines in real time using optical sensors embedded in the composite structure of HTLS conductors.

Optical sensing technology in high voltage environments has the advantage of being immune to electromagnetic interference and exhibits a low attenuation of the signal, making it well suited to applications in power transmission structures. The addition of Fiber Bragg Gratings (FBG) to standard single mode optical fiber with a total diameter of 250 microns or less creates the ability to measure temperature and strain of live lines in-service [5]. Monitoring an energized line using the sensors can be performed from miles away without conductive materials touching the lines.

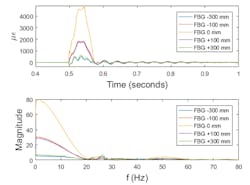

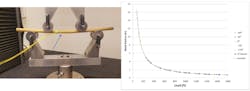

Signal processing of strains from static and dynamic loads can be used to identify conditions that can be damaging to the conductors. For example, in [2,5], ACCC composite cores were exposed to transverse low-velocity impact using the pendulum apparatus in Figure 3. It was found that low velocity transverse impact to ACCC hybrid composite cores produced the identifiable strain responses in Figure 4 and Figure 5 for very low and high impact energies of 0.01J and 33.1 J, respectively. The legend indicates axial distance from the center of the rod for each sensor along a single optical fiber.

Analysis of the data in Figures 4 and 5 can separate the transient and steady-state frequencies. The fundamental frequencies of the dynamic strain response can then be used to assess the structural health of the system [5]. Additionally, the precise readings of the strain responses can be used to determine the position of an impact relative to the location of FBG sensors along the conductor [5]. The ability to identify exact locations of dynamic events allows for better inspection and maintenance procedures for ACCC and other conductors.

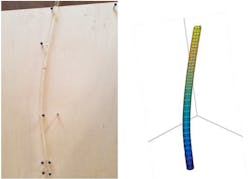

Monitoring of transmission conductors and other grid components using FBG sensors can be significantly enhanced by the incorporation of a novel algorithm recently developed at the HVT Center to perform three dimensional shape sensing [6]. An example of the application of the algorithm is shown in Figure 6 for an ACCC rod subjected to 4-point bending. Strain measurements produced by two adhered FBG sensors very accurately determined the bend radius of the rod. The solid curves are the analytically and numerically determined bend radius using the applied load and the material properties of the ACCC rod [6]. This unique approach works with two fixed sensors correctly positioned on cylindrical structures regardless of the applied bend direction. Knowing the instantaneous bend radius in any direction can identify excessive bending situations that can lead to permanent damage of the ACCC rods during installation and in-service.

Figure 7 demonstrates a more general application of the algorithm for three dimensional shape sensing of cylindrical structures subjected to arbitrary loading conditions. These and other monitoring techniques developed in the HVT Center may be adapted to work on standard ACSR and other types of overhead conductors. FBG sensors could also be used on towers, insulators and other types of HV structures where the presence of strong electric fields preclude the use of standard strain gauges.

The National Science Foundation Industry/University Cooperative Research Center for Novel High Voltage Materials and Structures is completing its fifth year of operation. Over the five years it has graduated 18 PhD and 14 Masters students from four large US universities and provided member directed research to 19 member companies including many major transmission companies and manufacturers. Member approval of projects ensures research is strictly industrially relevant. If you would like to learn more, please visit HVTcenter.org or contact Dr. Maciej Kumosa at [email protected].

[1] A. Alawar, E. J. Bosze, and S. R. Nutt, “A composite core conductor for low sag at high temperatures,” IEEE Transactions on Power Delivery, vol. 20, no. 3, pp. 2193–2199, 2005.

[2] D. H. Waters, J. Hoffman, E. Hakansson, and M. Kumosa, “Low-velocity impact to transmission line conductors,” International Journal of Impact Engineering, vol. 106, pp. 64–72, 2017.

[3] J. Hoffman, J. Middleton, M. Kumosa, “Effect of a surface coating on flexural performance of thermally aged hybrid glass/carbon epoxy composite rods,” Composites Science and Technology, vol. 106, pp. 141-148, 2015.

[4] E. Håkansson, J. Hoffman, P. Predecki, M. Kumosa, “The role of corrosion product deposition in galvanic corrosion of aluminum/carbon systems,” Corrosion Science 14, 10-16, 2017.

[5] D. H. Waters, J. Hoffman, and M. Kumosa, “Monitoring of Overhead Transmission Conductors Subjected to Static and Impact Loads Using Fiber Bragg Grating Sensors,” IEEE Trans. Instrum. Meas., pp. 1–11, 2018.

[Online]. Available: https://ieeexplore.ieee.org/document/8472255/

[6] J. Hoffman, D. H. Waters, M. Kumosa, “Shape sensing of polymer core composite electrical transmission lines using FBG sensors,” IEEE Trans. Instrum. Meas., in press.

The National Science Foundation Industry/University Cooperative Research Center for Novel High Voltage Materials and Structures is a T&D World Media Partner.

About the Author

Daniel H. Waters

Daniel H. Waters received his B.S. and M.S. degrees in Mechanical Engineering from the University of Denver (DU), in Denver, CO in 2013 and 2017, respectively. He is currently working towards a PhD. degree in mechanical engineering at DU. His research interests include mechanical testing of materials and design of associated testing apparatus, numerical simulations of composite structures, monitoring of structures using Fiber Bragg Grating sensors and others. He has already published two major papers on research topics associated with this article.

Monika Bleszynski

Dr. Monika Bleszynski is a research scientist and DU program director of the National Science Foundation Industry/University Cooperative Research Center for Novel High Voltage/Temperature Materials and Structures (HVT Center) at the University of Denver. She holds a bachelor’s degree in Biology from Saint Louis University, and has obtained her PhD in Materials Science in 2018 focusing on polymeric materials and computational modeling. Her previous work history includes software engineering and systems management at The Denver Post, where she specialized in systems administration. Dr. Bleszynski is currently researching environmental effects on polymers and polymer composites, including developing molecular dynamics simulations to create novel materials for extreme applications.

Maciej S. Kumosa

Dr. Maciej S. Kumosa received his Masters and PhD degrees in Applied Mechanics and Materials Science in 1978 and 1982 from the Technical University of Wroclaw in Poland. Between 1984 and 1990, he was a senior research associate at the University of Cambridge in the United Kingdom. He is currently a John Evans professor of Mechanical Engineering at DU and the director of the National Science Foundation Industry/University Cooperative Research Center for Novel High Voltage/Temperature Materials and Structures (HVTCenter.org). Dr. Kumosa's research interests include the experimental and numerical multiscale analysis of advanced materials for electrical, aerospace and other applications subjected to extreme in-service conditions. Dr. Kumosa has completed more than 250 publications in numerous composites, materials science, applied physics, applied mechanics, general science and IEEE international journals (124), conference proceedings (60), and national research reports (60). He also graduated 19 PhD and 19 MS students. Dr. Kumosa is on the Editorial Board of the Journal of Composites Science and Technology.