Two Types of Poles, One Transmission Line

As the Belgian transmission system operator, Elia has been a pioneer in Europe for its use of high-temperature low-sag (HTLS) composite core overhead line conductors. Additionally, the utility has designed compact transmission lines using insulated crossarms with the aim of increasing public acceptance along existing rights-of-way.

With this approach, Elia has had to tackle the issue of uprating a line within the same right-of-way (ROW). Built in 1966, the East Loop single-circuit 70-kV transmission line was approaching its end of life (65 years) and had insufficient load-transfer capacity to supply the region’s energy needs. Elia opted to invest €30 million (US$33.6 million) to replace and uprate the overhead line that connected the Bévercé, Amel and Bütgenbach substations. The utility uprated the line to 110 kV, which required innovation in the type of structures used to gain public acceptance.

The East Loop Project

Elia set the following requirements for East Loop:

- The 110-kV double-circuit line must be built as close as possible to the original circuit’s route and maintain the same ground clearance as that of the lowest phase conductor on the 70-kV circuit.

- The 110-kV circuit must be designed compactly with a minimal ROW, so the height of the crossarms is limited to minimize bending at the bottom of the concrete pole.

- The towers must have a small footprint and the transmission line must look similar to a distribution line, which is a familiar and acceptable feature in the Belgian landscape.

- The weight and length of the transported concrete poles must be limited to 20 tons and 32 m (105 ft), respectively, to comply with standard legislation, thus avoiding special access requirements.

Tower Technologies

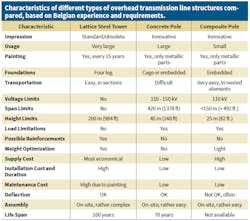

Traditionally, overhead transmission lines have been built using lattice steel structures. These towers are structurally stable and time-tested solutions, so there is logically no reason to consider a change. However, in recent years, new transmission line corridors that plan to use lattice steel structures have been delayed significantly because of ROW and aesthetic issues.

Solutions with narrow corridors and smaller footprints are requested for critical transmission corridors. The replacement of traditional lattice steel structures with monopoles is a significant step in this direction. Elia has not considered other types of structures such as guyed because they are only allowed in Belgium for use on temporary structures.

For the East Loop project, Elia decided to compare concrete poles with traditional lattice steel structures. Following are some of the advantages of concrete poles:

- Reduced ROW width

- Smaller foundation and smaller footprint occupying less land

- Fewer components and faster installation

- Significant wind-loading capability and reduced risk of local failure, because it is constructed with considerably fewer components

- Round and multisided design reduces the wind load

- Improved visual appearance and aesthetically more acceptable, depending on the proximity to public property

- Superior reliability under extreme wind conditions, as deformations may occur but complete failure is unlikely

- More flexible (in the case of a broken conductor, the greater deflection characteristic of concrete poles reduces tension in the affected span and bending at the base)

- Less maintenance, as no painting is required except for metallic parts.

On the other hand, following are some of the disadvantages of concrete poles:

- Site accessibility and logistics to the site must be assessed.

- More difficult to adapt because of the increased height and reinforcement.

- Cannot see through a concrete pole, which can be an obstacle from a visual standpoint.

- Concrete weighs significantly more than other structure types.

Because of some additional constraints with the East Loop project, Elia decided to compare composite poles, as well.

Structure Selection

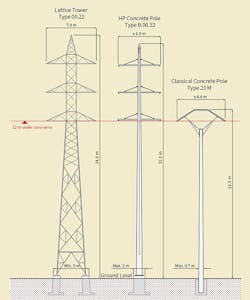

The existing 70-kV transmission line was supported by rectangular-section concrete poles with 0.91-m by 0.67-m (2.99-ft by 2.2-ft) sides and a diagonal of 1.13 m (3.71 ft). Elia decided to limit the diameter of the new tangent poles to 1.2 m (3.94 ft) to get as close as possible to the existing footprint. This decision also was based on the utility’s experience with a 150-kV line with steel poles where public acceptance decreased when the diameter exceeded 1.6 m (5.25 ft), as it gave the impression of a wall to residents in close proximity to the poles.

Because of fabrication tolerances and vertical requirements, Elia decided to work with a maximum of two sections per pole. A feasibility study of three sections revealed too many constraints, including extra costs because of the additional flange and on-site safety problems connecting the flanges at a significant height above ground level.

A comparison of the footprints, including the foundations, of the three tower types being considered for the new 110-kV transmission line confirmed a vast difference:

- 25 sq m (269 sq ft) for a lattice steel tower

- 4 sq m (43 sq ft) for a 110-kV concrete pole

- 0.6 sq m (6.46 sq ft) for the existing 70-kV concrete pole

For operational reasons, it was necessary to be able to climb the pole of the double-circuit line with one circuit energized. Therefore, the length of the crossarms was increased to maintain the specified safety clearances to climb the central ladder.

Based on the comparison of overhead line transmission structures and requirements for the 110-kV East Loop transmission line, Elia for the first time opted to use two types of structures in one project:

- High-performance concrete poles

- Composite poles.

Dual Approach

From the beginning, research and development was at the forefront of the East Loop project. Elia teamed up with two suppliers to develop high-performance concrete poles as an alternative to the conventional lattice steel towers used on transmission lines above 70 kV in Belgium. They specifically were developed to gain acceptance by the public, as existing single-circuit 70-kV transmission lines are supported by concrete poles and normally uprated using lattice steel towers.

The main advantages of high-performance concrete poles: They have a limited footprint and are more aesthetically pleasing. Feedback from local authorities was very positive during and after the completion of the first stage, thereby validating the improved public perception. Now, because of this positive feedback, Elia is reviewing the possibility of using high-performance concrete poles in its 150-kV overhead transmission line projects.

In addition to the concrete poles, three composite gantry poles with insulated crossarms were erected near the Bütgenbach substation as an experimental project. This location was selected because it takes advantage of the real capability of the poles in accordance with the Belgian and European Standard EN 50341 for the design of overhead line towers. This installation also was an opportunity to use insulated crossarms on a 110-kV line for the first time in Belgium, with the object of optimizing the dimensioning of the composite gantry poles to limit tower top deflections.

Because of the high flexibility of composite poles and considering their design capabilities as well as the maximum top displacement of 2.5% of the total pole height under normal conditions, it was decided to reduce the span length to less than 150 m (492 ft), half the length of a normal span. A gantry bipolar structure with a connection between the poles was used together with insulated crossarms to reduce the overall height of the pole to conform with the American Society of Civil Engineers (ASCE) Manual of Practice 104. Three-section poles were used for this experimental project so they could be nested into each other for transport to the site.

Line Design

The design of the transmission line took into consideration the time needed for constructing, as it was important to limit site occupation to increase public support for the project. The concrete pole foundations comprise a unique pad with a cage made of screwed steel bars to facilitate the connection to the bottom flange of the concrete poles, enabling one pole to be erected in a half day.

This project also gave Elia the opportunity to experiment with the construction of a short section of 110-kV line using composite poles. Because the utility did not have experience erecting this type of pole, it awarded a turnkey contract for construction of this section of the transmission line. Therefore, Elia was responsible only for designing the line and selecting the composite pole supplier and contractor.

Elia erected 93 pylons in total, consisting of 83 high-performance concrete poles, seven angle and dead-end lattice towers, and three composite gantry poles at Bütgenbach. Construction began in June 2015 and lasted 18 months. The new double-circuit 110-kV line, following the same route as the original, was commissioned in December 2016.

This project validated several key findings that can be used in future applications:

- Concrete poles can be used as an alternative in the construction of new double-circuit transmission lines in the voltage range of 70 kV to 110 kV, with the possibility of upgrading the voltage range to 150 kV.

- Pole erection was faster than anticipated and the use of galvanized reinforcing bars in the concrete poles should increase their long-term performance.

- The design of concrete poles and their visual impact can be further improved by using a single earth wire and insulated crossarms.

By constructing these new-generation structures in concrete or composite materials, Elia is carving out a position in the field of technological excellence where research and development with solid partners proves essential. This project received an award in 2015 from the Belgian Federation of Concrete as an outstanding application of using precast concrete.

Strong cooperation between Elia and the local authorities was needed to introduce the new support structures, which helped to gain public acceptance economically while maintaining the circuit’s high reliability. At the end of the East Loop project, local authorities and residents were highly satisfied with the integration of the new 110-kV double-circuit transmission line into the landscape.

About the Author

Jean-Francois Goffinet

Jean-Francois Goffinet is a senior expert on primary systems at Elia Engineering SA and has 20 years of experience in the design of overhead lines. He is a member of CIGRE, a Belgian representative of Study Committee B2 on overhead lines, a member of the International Electrotechnical Commission (IEC), and a member of the European Committee for Electrotechnical Standardization (CENELEC) work groups on conductors and overhead lines. Goffinet has been involved in more than 20 publications.

Nicolas Michalakis

Nicolas Michalakis is a senior expert in foundations, civil works and concrete poles, with 30 years of experience in this field.

Nicolas Blanpain

Nicolas Blanpain is a project leader at Elia Engineering SA with experience in overhead line projects in the southern part of Belgium.