Utilities face growing pressure from industry regulators to increase network reliability. As such, electricity supply reliability indicators, namely the system average interruption duration index (SAIDI) and system average interruption frequency index (SAIFI), are monitored closely. This results in a pressing need for solutions that enable faster location of faults, thereby reducing the time needed to restore power supply.

The majority of overhead medium-voltage (MV) distribution systems in central European countries are designed with a resonant earthed neutral whereby a variable arc suppression coil (ASC) — also referred to as a Petersen coil — is installed between the transformer neutral and earth in the source-of-supply substation. This iron-core reactor effectively limits the capacitive earth fault current flowing to earth in the event of an overhead line earth fault.

ASCs are installed mainly on rural MV overhead line networks, where about 90% of all faults are earth faults. Consisting of circuits with voltages ranging from 1 kV to 52 kV, European MV overhead line networks are designed with this form of compensated neutral point earthing, making it quite challenging and time consuming to detect and localize a single-phase earth fault.

Manual Location

From 2009 to 2017, Západoslovenská Distribučná A.S., a distribution network operator (DNO) and member of the E.ON Group in the Slovak Republic, installed more than 500 remotely controlled smart disconnectors on its 22-kV overhead lines. These disconnectors comprise a switching element, controlled remotely by the general packet radio service (GPRS) network, equipped with voltage transformers (VTs), current transformers (CTs) and electrical protection.

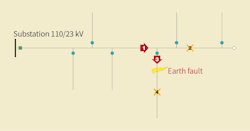

Therefore, if an earth fault occurs, simple protection indicators in the disconnectors are activated. A signal is sent to the supervisory control and data acquisition (SCADA) system indicating the section of line subjected to the fault. This alerts the load dispatching centre to disconnect the faulty section remotely, which restores power supplies to the healthy section of the distribution network.

Until recently, the exact location of an earth fault within the MV overhead line section was identified using manually controlled switches and visual inspections of individual overhead line sections, typically 5 km to 10 km (3.11 miles to 6.21 miles) in length. This process was both time consuming and physically demanding as network service employees often had to walk for long periods in difficult terrain. As an exact fault location is not always visible at first glance, finding the location could take several hours.

Earth Fault Location Device

To improve the earth fault location process, Západoslovenská Distribučná embarked on developing a handheld measurement device capable of determining the exact location of an earth fault. The ELF7 prototype, including the algorithm, was developed in-house by following these steps:

- Determining the voltage and current conditions on the MV overhead line during an earth fault

- Creating a mathematical model

- Testing the mathematical model with experimental earth faults

- Complex testing of the device with real earth faults on the MV network.

To verify the functionality and mathematical model of the prototype, more than 100 measurements were taken with experimental earth faults on the real MV network. Major focus was given to testing both high-ohmic earth faults and intermittent earth faults. The high-ohmic earth faults were simulated using an in-house-designed high-power water resistor, in which the value of resistance could be changed over a broad range. Intermittent earth faults were simulated using a spark gap, in which the value of breakdown voltage could be changed over a broad range.

Experimental earth fault measurements verified the consistency of the theoretical mathematical model with reality. Deviations between the mathematical model and the values measured by the device did not exceed 5%. All measurements taken with the device determined the relative location of the fault correctly. The parameters of the device were set according to the experimental earth fault measurement results and analysis of fault records. As a result, the device was able to accurately evaluate the relative position of the earth fault location in various situations.

Encapsulated in a durable plastic case that fits in the hand, the ELF7 earth fault location finder is an innovative alternative to static earth fault locators installed on MV overhead lines for protection. It provides a contactless way to determine the location of an earth fault in relation to where a measurement is being taken. The device makes it possible to identify the fault location quickly by taking a series of measurements.

After verifying the prototype’s functionality and finalizing the design, the Slovakian DNO worked with ELVAC A.S. to manufacture the ELF7 device.

Now In Use

Powered by a rechargeable battery, the ELF7 provides a contactless determination of the relative earth fault position from anywhere under an overhead line, whether the fault is located behind the measurement position (toward the end of the line) or before the measurement position (toward the feeding substation).

All the DNO’s network service employees are now equipped with the device. When they are sent to find an earth fault location, they take a series of measurements at suitable places under the MV overhead line. After each measurement, the device shows them in which direction the fault has occurred, and that is the direction they should proceed to locate the fault position. Using the device enables employees to find the fault location quickly.

The investment in this solution represented a fraction of the cost of installing a hardwired system to identify exact earth fault locations, and the time to find the fault ultimately is comparable.

The device was designed primarily for compensated MV networks with switching secondary resistors installed to increase the active component of the fault current in the event of an earth fault. In addition, a version suitable for isolated MV networks and MV networks with a low-impedance grounded neutral point was developed.

The design of the device is based on the measurement of the electric and magnetic fields beneath the MV overhead line. The electric field is measured by capacitive coupling between the measured electric line and the device's sensor. The magnetic field is measured by inductive coupling.

Results And Benefits

All network service employees were equipped with the ELF7 — a total of 102 units — at the start of 2018. Dozens of earth faults have been located successfully using the device, with no glitches or unexpected behaviour reported. The fault location process now takes approximately 20 minutes, which is a significant reduction in the time-consuming procedure used previously.

The ELF7 algorithm was tuned based on a long-term analysis of fault records acquired from actual earth faults. It is now also capable of locating even intermittent earth faults reliably, which are generally regarded as being one of the most difficult network faults to locate.

The Slovakian DNO has experienced significant benefits in using the ELF7 handheld measurement device on its MV overhead line network:

- Decreased the SAIDI and SAIFI network reliability indicators.

- Decreased the time taken to locate earth faults on MV overhead lines.

- Decreased the number of transient processes at the occurrence of earth faults, a phenomenon in which the voltage stress on insulation systems is the highest, often leading to short-circuit faults.

Martin Horák ([email protected]) received the Diploma Engineer Degree and his Ph. D from the Slovak University of Technology in Bratislava, Slovakia. Since 2006 he has been employed by the Západoslovenská distribučná (DSO) in the field of distribution network operation and protection. His research activities include compensated MV networks, power system protection and systems for fault location.

Sidebar: How The ELF7 Works

Consider the following situation: An earth fault occurs on a long medium-voltage (MV) overhead line routed through mountainous terrain. Using the ELF7 from Západoslovenská Distribučná A.S., the search process for locating the earth fault location is as follows:

The dispatch centre operator sends the network services employee directly to an easily accessible place located approximately in the middle of the affected line. The location is usually where the MV overhead line crosses a road or it is possible to approach with an off-road vehicle.

The network services employee stands under the MV line, approximately under the middle phase conductor. The optimal position to measure the electric and magnetic fields is to hold the ELF7 so the axis of the device is parallel to the line’s axis, as far away from the body as possible, roughly at neck height.

Simultaneously, the four main signal light-emitting diodes (LEDs) located on top of the ELF7 are visible. The ELF7 uses these four LEDs to communicate with the operator (the lighting of an LED is accompanied by a sound signal). When the device is turned on, only the green LED signal is illuminated, indicating it is ready to evaluate the location of the earth fault.

The network services employee then requests the dispatch center operator to energize the MV line. When the MV line is energized, the ELF7 automatically detects the increase in electric field intensity under the line and a blue LED lights up, indicating the evaluation algorithm is running.

As the evaluation algorithm runs, the ELF7 measures the electric and magnetic fields and determines the relative location of the earth fault in relation to the place of measurement. After several seconds, the device announces the result of the measurement with a red or yellow LED. If the red LED lights up, it means the earth fault is ahead (that is, toward the end of the line). If the yellow LED lights up, it means the earth fault is behind the operator (that is, in the direction the feeding substation). The MV line may then be deenergized.

If the first measurement was taken approximately in the middle of the faulty line section and the result was the red LED, it indicates the fault is ahead of the measurement position (that is, in the second half of the line from the source end). The dispatch centre operator then sends the network services employee to the middle of the lone section under scrutiny (that is, to approximately three-quarters of the overall line section length).

Network services employees moves to the specified location and repeats the same measurement process, relaunching the evaluation algorithm under the energized line. If the measurement results in the yellow LED lighting up, the fault is behind the operator (that is, between the first place of measurement and the second place of measurement). The suspected faulty section of the complete MV overhead line is reduced to a quarter of its overall length.

As a result of these gradual measurements, the network services employees come closer and closer to the fault location. For Západoslovenská Distribučná, after four measurements, the suspected section is usually so short the fault location can be found quickly with visual inspection. The entire process of locating a fault usually takes about 20 minutes.

About the Author

Martin Horák

Martin Horák received the Diploma Engineer Degree and his Ph. D from the Slovak University of Technology in Bratislava, Slovakia. Since 2006 he has been employed by the Západoslovenská distribučná (DSO) in the field of distribution network operation and protection. His research activities include compensated MV networks, power system protection and systems for fault location.