How Drones Are Revolutionizing Power Line Inspections: Georgia Power’s Success Story

For electric utilities and grid operators, uncrewed aircraft systems (UAS, or drones) are a force multiplier. Given a bit of special training and equipment, a small number of utility workers can keep an eye on miles and miles of power lines a day, or inspect dozens of transmission towers — all without sending people to work at height.

With more accurate inspections, lower costs and fewer risks to workers, it is no surprise that many utilities have chosen to train up their workers to be pilots and form their own in-house UAS departments.

I recently spoke with Jesse T. Watts, project manager for Georgia Power Transmission Co., who provided me some details on how his utility, a unit of Southern Co., got into the drone business and proved that UASs could be a tool for effectively and efficiently addressing potential power grid problems.

Georgia Power Co. owns 11,855 miles of transmission lines in total, as well as 78,583 miles of distribution lines. These lines run across terrain that is sometimes mountainous, hilly, forested, crowded and urban or remote and rural. The utility is also on the grow along with the state of Georgia itself, with 2,712,780 customers serviced as of December 31, 2022.

Liftoff

Southern Co.’s UAS got its official start in 2015 when it won its Federal Aviation Administration (FAA) Chapter 333 exemption. Since the federal government issued the Part 107 Certification, Southern has used both piloted aircraft and third-party contractors.

The utility currently employs more than 160 in-house pilots with more than 200 aircraft. Southern requires these pilots to complete extra training in addition to their Part 107 certificates.

Georgia Power Co. kicked off its UAS Transmission Tier II Working Group in 2018. This group started as a team of ten transmission subject matter experts who were also trained drone pilots. Their mission was to operate and test out more advanced UASs on work such as power line maintenance, line construction and property and casualty (P&C) field services.

These pilots were located across Georgia and selected for their skills learned in their other full-time jobs. Some were line workers, some specialists, some engineers and so on.

Piloting the Pilot Project

With a core group assembled, the utility moved on to pilot this new UAS-powered line inspection program in two phases. In phase one, the team would perform 1000 structural inspections on three transmission lines with a combination of drones and ground inspection crews. Lines were selected to demonstrate effectiveness in three different terrains found in the GPC service territory: Urban, rural and mountainous.

Comparing the effectiveness of ground crews with UAVs on line inspections under different conditions was one goal of the first phase. That effectiveness would be weighed based on the inspection results as well as safety and cost considerations.

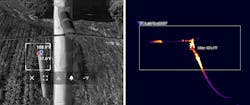

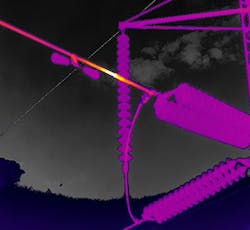

The aerial inspection checklist consisted of image collection as well as thermal inspection and analysis. The UASs took images on approach, zoomed in on approach, from overhead and zoomed in on departure as well as a final departure image.

The ground line inspection crews did their inspections after the drone, performing a typical ground inspection on the line segments.

In Phase II of the pilot, the team tackled 50% of the planned 2022 line inspection work plan with the transmission UAS pilot team. The group targeted inspections in all areas of the service territory with a goal of completing 50% of inspections within the first 6 months.

In this phase, the team’s objective was to help increase the utility’s commitment to innovation, efficiency and employee development. Specifically, this meant deepening the utility’s skill set with UAS technology, developing the team of pilots further, gathering feedback from all areas across the utility’s footprint in Georgia, compare costs at all transmission voltage levels and determine which workforce and technology resources might be needed to deliver the desired results.

Putting a Team Together

The UAS inspection teams used a project manager, who managed project operations, supervised data collection, made sure airspace restrictions were followed, trained line inspectors and pilots, and took notes on potential areas for improvement within the program.

A group of five full-time line inspection specialists were also on the team. These workers conducted all line inspections in accordance with industry best practices and Georgia Power policies. They collected text data and imagery to help generate a work plan for maintaining the inspected transmission lines.

The inspection specialist team had over 90 years of experience working on transmission lines and more than 3000 hours of combined UAS inspection flight hours logged. They performed tasks as varied and wide ranging as storm support, infrared inspections, switch inspections, UAS-based line pulling, fiber evaluations and UAS night operations.

Findings and Results

Once Phase I and II were complete, GPC found that its 3-worker UAS pilot team was able to complete inspections on 7000 structure locations in 8 months. GPC’s decisionmakers received reports on abnormal conditions and the imagery associated with those conditions immediately after the area inspection was completed.

The teams averaged 14 miles of power line inspections per day on average, with 1400 line miles inspected in total. This took about 1000 flight hours logged, with each structure averaging about 7 minutes to fully inspect with a UAS.

In total, the drone team discovered 5174 abnormal conditions on lines and structures as compared with 1150 abnormal conditions found by the traditional inspection team from the ground only. Of those, 35 conditions were considered critical and needed to be addressed as soon as possible. The team from the ground found 17 critical conditions by comparison.

For the problem areas identified, the drones took about 48,000 images for diagnosis and analysis. GPC found it could realize cost savings of about 60% on a yearly basis with drone inspections while producing improved image data sets, locating more critical problems on lines, generating clear documentation of repairs needing immediate attention, less environmental impact, resolving most inspection access issues, and delivering the added benefit of thermal imagery.

After the pilot project’s analysis, GPC also surmised that line inspection crews could conceivably lose familiarity with lines, access points and line inspection best practices if they relied exclusively on drones over traditional from-the-ground inspections.

Another drawback of drones is UASs can perform visual inspections only, and cannot for example hammer a pole above the groundline. This could lead to more rejected poles. Furthermore, there is a limited availability of ground inspection crews.

Deploying Drones Widely

Today, the UAS work teams have more and more sophisticated equipment to perform their work with, which is a good thing because they are performing a lot of important work. The team uses a mini-fleet of a half-dozen Jeep Wrangler 4XEs, 14 DJI M300 quadcopters with H20T payloads, ten DJI M30T quadcopters and three Skydio X10 quadcopters with thermal imaging capabilities.

With this experience and this equipment, the team has an average annual workplan today of:

- 10,000 to 15,000 structure locations

- 2,500 average line miles

- 100,000 average images collected

- 3,000 average flight hours

- 2,000 average data processing hours

The team can perform evaluations of the age of individual transmission assets, their overall condition, their potential deterioration, environmental concerns, the criticality of the line and the potential operations and maintenance cost to repair.

Comparing inspections performed of a similar area and equipment in two different years, the UAS team identified 37,904 total abnormalities in 2023 compared with 18,662 from the traditional on-ground team in 2020. Of those, 113 found by the drone pilots were potentially critical and in need of immediate repair compared to 46 critical problems located by the ground team. The drone pilots also discovered 1757 line health issues that the ground crew was not able to.

Drones are not the end-all, be-all for line inspections. There are still some tasks they cannot yet perform with existing technology. Their advantages in efficiency, cost-effectiveness, safety and precision, however, are easy to quantify.

About the Author

Jeff Postelwait

Managing Editor

Jeff Postelwait is a writer and editor with a background in newspapers and online editing who has been writing about the electric utility industry since 2008. Jeff is senior editor for T&D World magazine and sits on the advisory board of the T&D World Conference and Exhibition. Utility Products, Power Engineering, Powergrid International and Electric Light & Power are some of the other publications in which Jeff's work has been featured. Jeff received his degree in journalism news editing from Oklahoma State University and currently operates out of Oregon.