The Impact and Engineering of the Grain Belt Express HVDC Line

Key Highlights

- GBX will be the largest U.S. transmission line, spanning 800 miles and delivering 5 GW of power from Kansas to load centers in Missouri, Illinois, and Indiana.

- The project connects four grid regions, enhancing interregional power flow and grid resilience using advanced HVDC technology with VSC stations.

- Innovative engineering solutions, including custom OPGW cables and full-scale tower testing, mitigate risks like wire galloping and extreme weather impacts.

- Nearly 1,300 soil borings and aerial surveys informed foundation design and optimized tower placement, ensuring structural reliability and cost certainty.

- The project emphasizes reliability through features like black start capability, power flow reversal, and containment towers to prevent cascading failures.

Grain Belt Express (GBX) will be the largest transmission line in U.S. history. An 800-mile High Voltage Direct Current (HVDC) transmission megaproject, GBX is designed to deliver 5 gigawatts (GW) of power from southwest Kansas to load centers in Missouri, Illinois, and Indiana. Notably, GBX will be the first U.S. transmission line to connect four grid regions with domestic energy resources, including Associated Electric Cooperative Inc. (AECI), SPP, MISO, and PJM.

Designing An HVDC Megaproject

The unprecedented scale of GBX makes it a pivotal investment for today’s U.S. power grid. GBX will address 5 of the 35 GW of interregional transmission needs identified by the North American Electric Reliability Corporation (NERC).

As an open access and merchant transmission line, GBX has been developed with a clear focus on certainty — attentively managed technical, financial, regulatory, procurement, and schedule factors. Also as discussed in this article, being the largest domestic deployment of HVDC, GBX adopted state-of-the-art design practices to meet interrelated electrical, structural, and mechanical requirements to enhance long-term project performance.

By leveraging advanced HVDC technology with a Voltage Sourced Converter (VSC) station design, GBX delivers a vital transmission backbone that strengthens grid connections. To illustrate, GBX’s ability to reverse power flow enhances resilience under extreme power demand conditions; its integrated black start capability provides a stable pathway for power restoration during widespread outages. These features can help keep the lights on and reduce the risk of long, costly disruptions for households and businesses. Such far-reaching benefits are achieved with greater efficiency than conventional alternating current (AC) systems, which still make up most of the grid, underscoring why HVDC was the technology of choice for a project of this scale.

Building Certainty Early

Central to GBX development has been a focus on innovation that underpins diverse project scope definition and reliability outcomes. This was accomplished via a broad set of engineering efforts to safeguard performance and collectively de-risk the transmission line:

- Wire galloping — a high-amplitude, low-frequency oscillation which causes wires on transmission lines to move in a “jump rope” motion, sometimes even coming into physical contact with each other. Galloping posed both reliability and schedule risks, such as potential wire degradation, transmission tower and equipment damage, and even outages. Through a novel design approach, the project team reduced galloping risk to near-negligible levels while meeting GBX’s elevated reliability standards, thereby avoiding the need for approximately 180,000 anti-galloping devices or costly tower redesigns.

- Transmission tower foundations. Nearly 1,300 soil borings were completed along the 542-mile Phase I route, providing both confidence and cost certainty in foundation design while preserving flexibility for construction.

- Insulator testing. Placing a strong emphasis on defining testing requirements for the insulator assemblies that hold up and separate the electrical wires on each tower. These components are critical — they prevent electricity from ‘jumping’ to the towers or other wires, keeping the power safely contained within the lines. Each insulator assembly was carefully studied and sized to withstand extreme conditions, including powerful electrical surges, without failing.

- Multiple aerial survey flights. These captured detailed terrain and above-ground data across four states, enabling optimized tower placement and route planning.

- Proactive wire procurement. A long-term supply and manufacturing agreement was reached with Prysmian that includes a $22.5 million investment to expand its Williamsport, Pennsylvania overhead conductor facility. Notably, GBX’s first order of conductors will be manufactured exclusively using U.S. steel and aluminum and according to project-defined conductor specifications, including E3X® Technology. The total length of conductor exceeds 22 million feet. Working in partnership with Prysmian, GBX also developed a custom Optical Ground Wire (OPGW) for the project — an innovation that proved critical in mitigating wire galloping, as discussed in detail later in this article.

- Rigorous tower testing. Each of the project’s 9 unique tower types underwent full-scale testing to confirm they could reliably support the line and withstand controlling construction and operational load cases. This process not only confirmed structural integrity but also reduced the risk of late-stage design changes, helping keep the overall schedule on track.

Robust Towers, Reliable Transmission

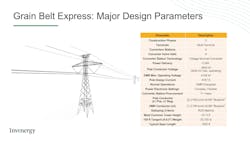

GBX’s custom-designed steel transmission towers feature a symmetric, vertical design. From the top, two OPGWs provide lightning protection for conductor wires below, two Dedicated Metallic Return (DMR) conductors enhance stability, and two Pole Conductors carry the bulk of electricity safely across the line. GBX is a ±600 kV HVDC system with a bipolar design — meaning one pole is operated at a positive voltage and the other at a negative voltage. The DMR provides a path to redirect extra current, keeping the two poles in balance and power flowing reliably. This configuration sets the GBX towers apart from conventional three-phase AC towers.

Update on Grain Belt Express:

Construction on Phase 1, which runs between Kansas and Missouri, is anticipated to begin in 2026, pending regulatory reviews. The project has secured all state approvals and a large portion of land agreements for Phase 1, and has awarded contracts for construction work.

- Federal Loan Cancellation: The U.S. Department of Energy (DOE) terminated its conditional loan guarantee.

- Project Continuation: The project developer, Invenergy, maintains its commitment to the project and is pursuing other financing options.

- Phase 1 Construction: Anticipated to start in 2026, pending regulatory reviews.

- Landowner Agreements: The project reports that voluntary easement agreements are complete for a substantial percentage of the Phase 1 route

- Regulatory Approvals: The project has received all state approvals, including from the Kansas Corporation Commission and the Missouri Public Service Commission.

- Phase 1 Route: The Kansas Corporation Commission has approved the route for the AC Collector System, which is part of the overall project.

- Contracts: The developer has awarded contracts for construction, including significant awards to Quanta Services and Kiewit Energy Group Inc.

- Phase 2: A schedule for Phase 2, which extends from Missouri to Indiana, has not yet been announced, but will follow Phase 1.

The GBX transmission line also uses a family of nine free-standing lattice tower types, including six “containment” towers designed to prevent cascading failures in the unlikely event of a tower collapse, conductor break, or severe weather damage. Two towers were specially designed for the 3,700-ft Missouri River crossing. Average tower heights range from roughly 120 to 220 feet above ground, with river-crossing structures reaching up to 315 feet. Each tower type underwent extensive full-scale testing to build confidence it could handle extreme loads and weather conditions, thus validating performance and reducing risk.

Full-scale testing of each unique tower type over 18 months included hundreds of tons of steel and more than 100 worst-case loading scenarios. Loads ranged from unbalanced broken wires to concurrent extreme wind and ice weather conditions. Early testing provided critical insight, allowing timely adjustments and keeping the overall project schedule on track. These milestones not only confirmed the towers’ structural integrity but also streamlined construction planning and reduced the risk of costly design changes later in the project.

Tackling Galloping via Innovative OPGW

The project route passes through areas with steady winds, occasional ice, and spans averaging 1,500 feet, all of which increase the likelihood of wire galloping and the need for reliable engineering solutions to manage this phenomenon. Because the DMR is a critical component of the line’s reliability, galloping and potential contact with other wires can lead to service interruptions. Addressing this risk was therefore essential to maintain safe and efficient operation of this backbone transmission line.

After Invenergy assumed ownership the project underwent significant design upgrades in an attempt to broadly de-risk the project, including the formal addition of galloping as a design criterion. Preliminary engineering analyses indicated potential physical contact between wires due to galloping across nearly 75% of the line, with the DMR emerging as a key concern.

Protecting this critical wire demanded creative solutions under pressure. Despite an accelerated schedule for parallel tower design and full-scale testing, the team successfully navigated the overlapping wire risks, transforming a major technical challenge into a demonstration of engineering resilience and innovation.

The breakthrough to the galloping wire challenge came through a custom OPGW. The cable was refined to be slimmer, stronger and lighter, which reduced sag — the natural dip a line takes between towers. With less sag, the swinging wire galloping motions caused by ice and wind were also reduced, dramatically lowering the risk of wires overlapping. Remarkably, it was a minor adjustment in the fiber coating — something almost invisible — that allowed for this new wire design to be effective, ultimately shaping the reliability of the nation’s largest transmission line project.

The results were striking. The percentage of the transmission line experiencing galloping and wire overlap dropped from roughly 75% to 2%, with many of the remaining spans with this issue showing much smaller galloping overlap amplitudes. Targeted anti-galloping devices will manage these few remaining spans, but most of the line now benefits from a solution integrated directly into the OPGW design. The custom cable solution proved to be the most effective approach: simpler to integrate and more cost-effective than modifying tower designs or adding a large amount of additional hardware to the line, which are more traditional strategies.

Raising the Reliability Bar

The efforts presented highlight the importance of custom solutions for complex long-distance transmission lines. Standard OPGW can sometimes be insufficient for large-scale projects and tailoring cable characteristics can mitigate dynamic behavior and wire interaction. Combined with proactive measures — targeted geotechnical analysis, extensive aerial surveys, rigorous tower testing, and well-vetted insulator designs — these and other risk-mitigating solutions provide a model for future high-capacity lines.

Beyond individual design details, GBX further highlights HVDC’s growing role as key infrastructure for the U.S. grid. High-capacity, long-distance HVDC lines deliver power more efficiently and reliably than traditional AC systems, minimizing losses over hundreds of miles. In addition to efficiency, HVDC provides unique operational advantages, offering unmatched flexibility, resilience, and control, establishing a new standard for domestic bulk power transmission.

The integrated and future-focused approach to critical large-scale transmission projects showcased by GBX will deliver the certainty needed to enhance reliability, support construction readiness, and ultimately strengthen the U.S. grid in this period of historic energy demand growth.

Read More

About the Author

Jillian Edwards

Jillian Edwards, PE ([email protected]) serves as a Project Engineer at Invenergy where she supports HVDC projects in pre-construction and early development, as well as numerous generation-tie line projects. She has been a member of ASCE and the Structural Engineers Association of Illinois since college. She earned a bachelor’s degree in civil engineering from the Illinois Institute of Technology.

Aaron White

Aaron White, PE ([email protected]) serves as a Senior Director at Invenergy where he has led several key initiatives, including positioning Invenergy as a leader in HVDC, negotiating long-term supply agreements with strategic partners, and leading team members in contributing technical content for CIGRE, IEEE, ASCE, and APLIC. He earned a bachelor’s degree in civil engineering from the University of Utah

David Gelder

David Gelder, PE, PMP ([email protected]) serves as a Senior Manager at Invenergy where he manages a portfolio of several dozen “gentie” projects in development and construction across 25 states and 2 provinces. He earned a bachelor’s and master’s degree in civil engineering from Brigham Young University and an M.B.A from the University of Utah.