The wind-induced response of structures has been a significant subject of engineering research over the past 40 years. Tall, slender buildings, chimneys, antenna towers, high-mast light standards, cantilevered signal structures and, yes, even tall, slender transmission structures can be subjected to wind-induced vibration that results in an excessive vibration response, potential fatigue damage and even collapse.

It has been more than 20 years since many state highway departments experienced significant damage and collapse of tall, slender light standards made of tall, tapered multisided thin-walled high-strength steel. This led to a research effort at Lehigh University in 1998 for which report No. 98-03 was published, Fatigue-Related Wind Loads on Highway Support Structures: Advanced Technology for Large Structural Systems.

This stimulated more research efforts to understand the problem better and lead to new design provisions. Stronger steels and lighter-weight structures with low levels of damping have made consideration of vibration and fatigue more important than ever in today’s environment.

These problems, along with challenges in popular welding methods, led to more research efforts to develop design standards for cantilevered signal, sign and high-mast light support structures. Researchers at Purdue University developed design guidelines for National Cooperative Highway Research Program project 10-74, captured in the 2011 report entitled Development of Fatigue Loading and Design Methodology for High-Mast Lighting Structures. This report led to guidelines found in present-day design standards.

Today, engineers designing these types of structures in the highway industry are accustomed to using the Standard Specifications for Structural Supports for Highway Signs, Luminaires and Traffic Signals, published by the American Association of State Highway and Transportation Officials (AASHTO). This publication provides guidance to designers and manufacturers for analysis methods in Chapter 4 and fatigue resulting from wind-induced vibration in Chapter 11.

Current Design

Designers and manufacturers in the transmission line industry can learn from the lessons that came out of the highway industry. The fact is most designers today of tall, tapered multisided thin-walled high-strength steel transmission poles base their design on American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) standard 48, Design of Steel Transmission Pole Structures, as published by ASCE. This standard and its forerunner document, called ASCE Manual 72 Design of Steel Transmission Pole Structures, contain valuable time-tested design provisions developed over many years of successful applications in the industry.

While problems with wind-induced vibration are well known in the industry, no formal design provisions for vibration analysis and fatigue design are contained in this standard. It is well known but little publicized that some projects have experienced excessive vibration and fatigue problems, resulting in costly field modifications, repair and extended downtime.

These problems were the subject of a panel discussion at the 46th Annual Transmission and Substation Design and Operation Symposium held in Dallas, Texas, on Sept. 11-13, 2013. The problems can be traced to changes in the industry that have evolved over time, including lack of design provisions for wind-induced vibration, newer high-strength steel materials, manufacturing and welding practices, and assembly and erection practices.

New Research Studies

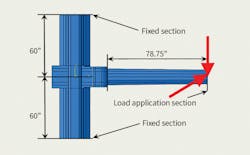

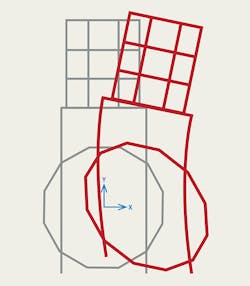

The good news is more experience has been gained in understanding the problems and developing new guidelines for designers and fabricators. Recent research at Purdue University, where full-scale fatigue tests were conducted on a widely used industry-standard arm-to-pole connection detail, has led to better understanding of design and welding issues that will help to inform the industry and lead to better performance in the field.

Researchers at Purdue also performed finite element studies of alternate connection details that will lead to more robust arm-to-pole connections with enhanced fatigue resistance. New design guidelines, better understanding of the site wind climate, careful detailing, stricter welding specifications and careful shop inspection all are key to improved performance. In addition, new analysis methods, guidelines for avoiding wind-induced vibration during the design stage and methods for field retrofit with damping devices currently are being studied.

This year’s ASCE/SEI conference in Atlanta, Georgia, U.S., will include a session discussing the new research at Purdue as well as recent experience and guidance from knowledgeable wind engineers, fatigue experts and welding and inspection engineers who have been active in the industry for many years.

Understanding the Problem

Extensive field monitoring of tall, slender steel pole structures in the highway industry and, more recently in the transmission line industry, has provided great insight into the problem of wind-induced vibration. Consideration of the following is key to a better understanding of the problem and how to avoid it:

- Wind climate at the site must be considered, including wind speed and direction during a typical annual period. It is well known wind-induced vibration (vortex shedding) can occur in relatively low winds speeds (12 mph to 30 mph) that produce many cycles of loading. Wind speed, direction and frequency of occurrence are important parameters that can dictate the risk of vibration.

- Flexibility of standard arm-to-pole connections and how to model the connections in a structural analysis model also must be considered. Typically, these connections in large-diameter, thin-walled cross-sections are considerably more flexible than fully rigid moment connections.

- Boundary conditions at the conductors and foundation should be considered, especially axial stiffness of the conductors and soil-structure foundation conditions.

- Mode shape and frequencies of the structure must be considered. They are complex and contain many possible modes of vibrations. A detailed vibration study can help to avoid wind-induced vibration problems. Experience seems to indicate few transmission structures are evaluated for mode shape and frequency in the design phase. This is contrary to many other types of engineered structures subjected to wind load.

- Key vibration parameters should be considered, such as the Scruton number, Strouhal number, Reynolds number and damping levels at various modes of vibration. These characteristics are important in determining the potential for vortex shedding of the arm, pole and structural system overall.

- Welding details and practices that lead to fatigue problems from wind-induced vibration should also be taken into consideration.

- Recent and past research has shed light on these important characteristics and how they affect performance, but more research is needed to cover the wide variety (for example, wind climate, height, member slenderness and boundary conditions) experienced in steel pole transmission structures

The Way Forward

Just as the highway industry learned from wind-induced vibration in high-mast lighting structures, so, too, can the transmission industry learn from this new research and future research studies that can greatly reduce the risk of fatigue problems at a reasonable cost. The hope is future design specification provisions will be developed based on new and upcoming research to guide designers and fabricators in developing more fatigue-resistant designs with improved long-term performance.

Lawrence (Larry) Griffis, PE, is a senior consultant with Walter P Moore and Associates Inc. He is past chairman and current member of the American Society of Engineers (ASCE) Task Committee on Wind Loads, which is responsible for developing the wind design provisions of ASCE 7 standard on Minimum Design Loads and Associated Criteria for Buildings and Other Structures referenced in most local and national building codes.

About the Author

Larry Griffis

Senior Consultant

Lawrence (Larry) Griffis, PE, is a senior consultant with Walter P Moore and Associates Inc. He is past chairman and current member of the American Society of Engineers (ASCE) Task Committee on Wind Loads, which is responsible for developing the wind design provisions of ASCE 7 standard on Minimum Design Loads and Associated Criteria for Buildings and Other Structures referenced in most local and national building codes.