Four Wind Farms Constructed at Once

On New Mexico’s blustery eastern plains, an army of construction crews built in a little over a year the largest wind farm complex ever constructed on land at one time. Pattern Energy Group LP started commercial operation of this largest single-phase construction of renewable power in American history at the end of 2021. Collectively known as Western Spirit Wind, the suite of four wind farms spans nearly 120,000 acres (48,562 hectares) across three counties in New Mexico. The projects total more than 1050 MW of wind energy, equal to enough annual electricity production for the needs of more than 900,000 people.

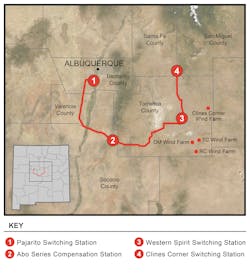

Pattern constructed the wind farms near the eastern terminus of the 155-mile (250-km) long, 345-kV Western Spirit alternating-current transmission line, the longest line constructed in New Mexico in 35 years. The transmission line interconnects at the existing Public Service Co. of New Mexico’s (PNM’s) Clines Corners substation and the newly constructed Pajarito substation near Albuquerque. The Pajarito substation was required to interconnect the project to the Western Spirit switchyard, a major 345-kV facility, and the Abo series compensation station. The Western Spirit switchyard serves as the point of interconnection for the four wind farms, and the Abo series compensation station maximizes the line’s power flow.

Designed to deliver electricity generated by New Mexico’s powerful winds to the state’s grid and broader Western markets, the Western Spirit Wind transmission project is a first-of-its kind public-private partnership between Pattern Energy and the New Mexico Renewable Energy Transmission Authority (RETA), which jointly developed and constructed the line, compensation station and switchyard. The line was transferred to PNM under a build transfer agreement between Pattern Energy, RETA and PNM. PNM now owns and operates the line and associated facilities.

The Need For Wind

Western Spirit Wind comprises four wind power facilities that use a total of 377 GE wind turbines ranging from 2.3 MW to 2.8 MW. The turbine towers are between 80 m and 114 m (262 ft and 374 ft) tall, enough to optimize the use of the resource at each facility. Blattner Energy Inc. constructed each of the wind farms in under a year.

New Mexico is one of the fastest-growing states for wind energy construction, boasting 2723 MW of installed capacity, with another 1447 MW under construction. California electricity demand is driving much of this development. New Mexico wind tends to pick up at sunset hours when California’s solar facilities stop operating, which influenced Pattern Energy to develop Western Spirit and others also to create large wind projects in the region.

Pattern is the largest wind developer in New Mexico. Even before the Western Spirit Wind development, it operated 550 MW of wind farms near Clovis that now supply renewable electricity to utilities in California and other Western states. Pattern also is developing more than 3000 MW of additional projects in the state.

Extensive Collaboration

Successfully building the Western Spirit Wind project in a single phase required teams of construction workers in the state and design personnel across the U.S. to collaborate extensively. The sheer size and scale made the project complex enough, but it was further complicated by having to coordinate the supervisory control and data acquisition (SCADA) and metering systems for multiple entities taking the generated power.

The SCADA and metering systems needed to integrate with PNM, the Tri-State Generation and Transmission Association Inc., the California Independent System Operator (CAISO), the Los Angeles Department of Water and Power, San José Clean Energy and Pattern’s operation control center. These organizations have different standards, and Pattern’s system needed to be designed in such a way it could meet all those requirements — no easy task.

For the transmission line and switchyard, now owned by PNM, Pattern engaged POWER Engineers Inc. for preliminary design, estimating and permitting support, as well as owner’s engineering services. Pattern also used POWER for the SCADA design work for all four wind farms and to seamlessly integrate the wind farms’ SCADA with the Western Spirit switching station’s SCADA network.

Pattern used NovaTech’s Orion remote terminal units as the substation computers. Integrating SCADA and metering systems to satisfy the requirements of all the agencies involved required proper planning, testing and real-time changes until the systems met the teams’ needs. This due diligence led the agencies to sign off on the project. Pattern moved from generating test energy to generating commercial energy.

GE initiated the Abo series compensation station design in mid-2020. This facility design required coordination with the transmission line design, communication design, SCADA interfaces and remedial action schemes, as well as an understanding of the existing and future system operations. Pattern’s internal staff, GE’s management and technical staff, and POWER’s team supported this work from initiation of the design to energization.

Commissioning Coordination

Coordinating commissioning of the four separate wind farms, two PNM interconnections, new switching station and new compensation station, with the goal of full-capacity energization by the end of 2021, represented a significant technical challenge. This effort involved collaboration among the wind farms’ engineering, procurement and construction (EPC) companies, the EPC power line and station constructors, the series compensation constructor, PNM contacts and Pattern’s leads.

Completing this complex puzzle required creating the unique role of a commissioning coordinator. The coordinator helped to ensure the testing and commissioning activities of the dozens of contractors and subcontractors were well synchronized to meet the critical commercial operation deadline.

The Western Spirit switching station had an initial energization target for the northeastern leg of the transmission line in mid-July 2021. A review of responsibilities leading to that energization revealed a need to perform significant SCADA programming and commissioning activities at the station about three weeks before the target date.

Through extensive planning, coordination and collaboration, teams of experts in SCADA, testing and energization, and others tackled the projects one bite at a time to get them done. As a result, the initial target date was delayed only about a week and Pattern successfully energized the station in July 2021.

The Western Spirit switchyard encountered some equipment setbacks as well as design and construction revisions that compressed the schedule and presented challenges in developing the relay settings. The interfaces with the wind farms and with PNM required significant programming and coordination during testing and commissioning of the project.

This commissioning process occurred in two phases.

- The first phase, the Northern phase, included the transmission interconnection to PNM’s Clines Corner station and connection to one of the wind farms. This established the energization and operation of the station.

- The second phase included the remaining wind farm connections, energization of the line from the Western Spirit station to the Abo station, and the line from Abo station to Pajarito station.

This two-phase approach enabled the wind farms to move forward with synchronization in the grid while continuing progress on the Western phase. All these steps required coordination at the Western Spirit station. On-the-ground testing personnel with office support remained at the development site from mid-July 2021 through December 2021, until Pattern tested the project and turned it over to PNM.

Successful Execution

All this close cooperation and planning among the owners, contractors, utilities and construction manager, Aegean Energy Group, led to a successful project execution during a pandemic. With the magnitude of the project and number of landowners and permitting agencies involved, everyone held a high focus on quality and coordination during design and construction.

Western Spirit’s wind power is now helping Western energy markets to supply energy from a mix of resources to meet customer demand. However, it is just one part of the renewable energy story in New Mexico. Pattern Energy looks forward to completing other wind projects and related infrastructure in the state.

David Janssen ([email protected]) is a project director with Pattern Energy Group LP, with more than 20 years of global experience in the renewable energy industry. He started his career with a leading wind turbine supplier and has installed several gigawatts of power plants all over North America, working from coast to coast in Canada and in over 20 states in the U.S. For the past 15 years, he has worked with some of the largest developer owner/operators in the world in engineering, construction, and project management for renewable energy and transmission. In his spare time, he competes on BattleBots, and he is a member of ASCE and the IEEE.

Darel Tracy ([email protected]) is a senior project manager with POWER Engineers Inc., with considerable experience in both utility and consulting engineering. He specializes in project engineering management of multidisciplinary projects, including right-of-way coordination, public process, transmission, distribution and substation design coordination. His experience includes T&D design as well as familiarity with national, state and local permitting, including National Environmental Policy Act, Bureau of Land Management and U.S. Forest Service coordination. He has extensive experience in public meetings and presentations for city and local permitting agencies.

Mark Reynolds ([email protected]) is a senior electrical engineer with experience in the development, design, implementation and marketing of alternating-current (ac) and direct-current (dc) power systems. He has specialized expertise in reactive compensation, flexible ac transmission systems and high-voltage dc (HVDC) systems and their application to improve the performance of systems through 500 kV. His career includes 25 years with Bonneville Power Administration, where he was instrumental in the development and installation of innovative compensation systems, including fixed series capacitors, thyristor-controlled series capacitors and other shunt static reactive volt-ampere compensation (SVC) systems. He also served as a consultant with Siemens AG to develop and market state-of-the-art ac compensation and HVDC systems. He was one of the principle working group members who drafted and published significant documents covering the specification development for SVC systems and field-testing of SVC systems.

For More Information

Aegean | www.aegeanenergygroup.com

Blattner Energy | www.blattnerenergy.com

GE | www.ge.com

NovaTech | www.novatechautomation.com

POWER Engineers | www.powereng.com

Pattern Energy | www.patternenergy.com

About the Author

David Janssen

David Janssen ([email protected]) is a project director with Pattern Energy Group LP, with more than 20 years of global experience in the renewable energy industry. He started his career with a leading wind turbine supplier and has installed several gigawatts of power plants all over North America, working from coast to coast in Canada and in over 20 states in the U.S. For the past 15 years, he has worked with some of the largest developer owner/operators in the world in engineering, construction, and project management for renewable energy and transmission. In his spare time, he competes on BattleBots, and he is a member of ASCE and the IEEE.

Mark Reynolds

Mark Reynolds ([email protected]) is a senior electrical engineer with experience in the development, design, implementation and marketing of alternating-current (ac) and direct-current (dc) power systems. He has specialized expertise in reactive compensation, flexible ac transmission systems and high-voltage dc (HVDC) systems and their application to improve the performance of systems through 500 kV. His career includes 25 years with Bonneville Power Administration, where he was instrumental in the development and installation of innovative compensation systems, including fixed series capacitors, thyristor-controlled series capacitors and other shunt static reactive volt-ampere compensation (SVC) systems. He also served as a consultant with Siemens AG to develop and market state-of-the-art ac compensation and HVDC systems. He was one of the principle working group members who drafted and published significant documents covering the specification development for SVC systems and field-testing of SVC systems.

Darel Tracy

Darel Tracy ([email protected]) is a senior project manager with POWER Engineers Inc., with considerable experience in both utility and consulting engineering. He specializes in project engineering management of multidisciplinary projects, including right-of-way coordination, public process, transmission, distribution and substation design coordination. His experience includes T&D design as well as familiarity with national, state and local permitting, including National Environmental Policy Act, Bureau of Land Management and U.S. Forest Service coordination. He has extensive experience in public meetings and presentations for city and local permitting agencies.