Refining the Scoring for Individual Gas Elements

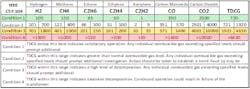

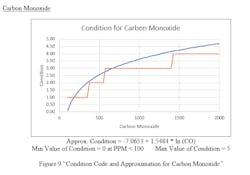

The DGA scoring reference uses IEEE C57.104 condition codes [1] as shown in Figure 1. These codes are integers from 1 to 4, where a lower number is better. An integer base for the condition codes allows for the possibility of an exaggerated move in condition if the value is near the edge for a particular code. Using curve fitting to interpolate between whole numbers allows for granularity thus allowing more insight for small changes. Figure 2 shows an example by plotting the hydrogen’s ppm value vs the IEEE condition code using both methods.

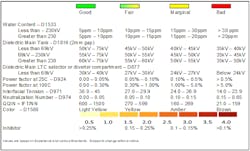

Refining the Scoring for the Oil Quality Elements

Oil quality condition code interpolation can be also be approximated. See below the plots of various curves. Note: Color is reported in increments of 0.5 and no curve is needed.

The approximation curves shown above calculate the approximate condition code for a single sample. IEEE C57.104 also gives condition codes for gassing rates over time when looking at the change between samples taken on the same piece of equipment on different days. The same process can be applied to develop more approximation code curves.

Key Element 1 Assembly (DGA)

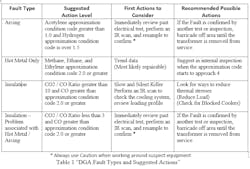

The Score should start by determining the category of the fault. The three most serious categories are Arcing, Hot Metal, and Insulation. A fault can exist in one or more of the three categories.

Arcing Score: If acetylene approximation condition code is greater than 1.0 and hydrogen approximation condition code is over 1.5, the arcing score is the value of the acetylene approximation condition code. If the hydrogen approximation condition code is 1.5 or less, the arcing score is 50% of the acetylene approximation condition code.

Hot Metal Score: The Hot Metal Only Score is the maximum approximation condition code looking at the three approximation condition codes from methane, ethane and ethylene.

Insulation Score: The Insulation Score is the approximation condition code of CO score.

The score for Key Element 1 is obtained by starting with a base of 10 (healthy transformer) and subtracting 2 times the maximum approximate condition code when looking at the three cases (Arcing, Hot Metal, and Insulation).

Equation 1: Calculating Key Element 1 - DGA

Using this approach, a fleet wide view of Key Element 1 will begin the process of focusing the resources. Refer to Figure 17 for a visual plot to understand the DGA health of the fleet. The same methodology can be used to plot the first three Key Elements and the final THI.

Key Element 2 Assembly (Oil Quality)

The subcomponents should be broken down to determine what is involved in scoring Key Element 2. After evaluating the scoring of the seven subcomponents, if any one of the chemical properties have deteriorated to the point of 3.0 or greater, the oil needs to be reconditioned or reclaimed. Reclaiming the oil is more expensive and more involved than reconditioning the oil.

Reconditioning the oil is more widely known as vacuum processing of the oil. This process removes moisture from the oil. In most cases, all of the oil is removed from the transformer and stored in a tanker while vacuum is applied to the transformer. This is a lengthy process that takes a minimum of three days. More time might be required depending on the size and wetness of the transformer. Also, any time oil is added to a transformer, the oil must be vacuum processed to prevent moisture from entering the transformer. While vacuum is applied to the transformer, the oil in the tanker is processed with heat and vacuum. After vacuum drying the transformer and reconditioning the oil, the dielectric and moisture numbers will improve. The power factor may improve if the contamination was because of moisture in the oil. Most likely the color will not improve because the filters only remove particles down to five microns.

Reclaiming the oil requires an additional filtering process in addition to the reconditioning process. This filter is composed of Fuller’s Earth (or equivalent). Fuller’s Earth is a special filter made from sedimentary clay that will filter out polar compounds from aging oil. It also strips out the oxidation inhibitor in the process. So the last step in the reclamation process is to add back the oxidation inhibitor to 0.3%. Reclaiming the oil will raise the IFT and lower the NN. In some cases, the temperature is raised to the aniline point, where the oil becomes its own solvent and starts to remove any sludge that has formed. This is a very time-consuming and expensive process. In some cases, it is less costly to replace the oil than reclaim it. Oil reclamation should be scheduled if the IFT and/or NN numbers are running greater than 3.0 because once the oil starts to sludge, then the sludge will start to deposit on the winding insulation. Next, if left untreated, the sludge will bake on the insulation and cause a dramatic effect by preventing the oil from properly cooling the windings. This leads to accelerated ageing of the transformer.

The score for Key Element 2 is obtained by starting with a base of 10 (healthy transformer) and subtracting 2 times the maximum approximate condition code when looking at moisture, dielectric, power factor, interfacial tension and neutralization number. Color and inhibitor codes are not used to drive the scoring. But the Subject Matter Expert (SME) can take the analysis of all subcomponents to construct and justify maintenance activities.

Equation 2: Calculating Key Element 2 – Oil Quality

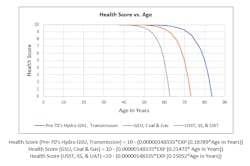

Key Element 3 Assembly (Age – Degradation Curve)

The Age is related to the “bathtub curve” shown in Part 2. It simply takes the “bathtub curve” and flips it upside down and then sets the maximum value to a score of 10. A value of 10 is defined as the minimum probability of failure. The probability of failure stays nearly constant throughout most of the transformer’s life. However, this changes dramatically as the transformer approaches end of life. Refer to Figure 18 below.

Key Element 4 Assembly (Significant Findings from Tests / Inspections)

Key Element 4 is unique since it is a multiplier. No matter the results in the first three Key Elements, some issues dramatically affect the overall health. An analogy with the human body can be used. If a person has a broken leg or is knocked unconscious, the overall ability to perform a given task is impaired. These types of problems are independent of the health or age of the major systems.

Equation 3: Calculating Key Element 4

Other issues can be added but listed below is a recap from Part 2. [2]

Power Factor testing

Investigate Rating on High Side Bushing(s) > 100kV - C1 Power Factor – 50%

Investigate Rating on High Side Bushing(s) > 100kV - C2 Power Factor – 60%

Investigate Rating on Other Bushing(s) C1 Power Factor – 70%

Winding Resistance

Measured Resistance Greater than +/- 5% from Factory Test – 30%

Transformer Ratio

Measured Ratio Greater than +/- 1.0% from Factory Test – 30%

Infrared Inspection

Bushing Cap Temperature Rise Over Ambient > 35C – 30%

Bushing Cap Temperature Rise Over Ambient > 10C and < 34 – 80%

Two or more Blocked Coolers or Radiators – 30%

One Blocked Cooler or Radiator – 80%

Visual Inspection

Pegged Low Oil Level Bushing(s) – 30%

Oil Leak on a Bushing(s) > 100kV – 50%

Low Oil Level High Side Bushing(s) – 70%

Main Tank - Oil Seep (Oil not dripping to the ground) – 90%

Main Tank - Oil Leak (Minor amount of oil hitting the ground) – 80%

Main Tank - Oil Leak (Oil absorbent pads used for oil leaks collection) – 60%

The Assembly for the THI (Final Score)

The Key Elements collected above meet the criteria of obtainable and routinely updated information collected as part of the preventive, corrective and predictive maintenance program. Also, this article has discussed the meaningfulness of the scoring criteria which include industry guidelines and numerical standards for each subcomponent.

Equation 4: Calculating the Transformer Health Index

Summary

The simplicity of the proposed THI methodology allows for Key Elements 1 through 3 to be automated, which translates to cost savings and efficiency. Key Element 4 allows the SME to have input and give this process the “human touch”. This is the best of both worlds that will allow for the most creditable story when the SMEs and maintenance crews are communicating with the management team and executives. Often, the technical issues are known at the SME and crew levels but their story cannot be communicated until a failure occurs. The management team and executives understand the financial limitations but often have a hard time knowing which pieces of equipment are at the top of the risk chart. The THI gives an overall picture of the fleet in one simple chart similar to Figure 17. If a picture is worth a thousand words then a THI graph is worth a million dollars.

References

[1] IEEE C57.104-2008, “IEEE guide for the interpretation of gases generated in oil-immersed transformers”, IEEE 2008

[2] Goff, Mark B. “Transformer Tier 1 Asset Health Index Scoring”, TecCon 2017 North America Conference