Whether tracking a package, a phone or even kids, it almost seems natural to know the location and status of distant entities in real time. In reality, the alignment of various sources of data and functions that actually make tracking features available is a tremendous technological achievement that depends on global positioning data, atomic clocks, fiber-optic communications and robust computing hardware. With these resources, synchronized observations go far beyond tracking widgets and people; they make it possible to measure the speed of light precisely and identify elusive particles in physics.

These same techniques are being developed by electric utilities to achieve something previously not possible: real-time situational awareness across an increasingly complex electric distribution system. Phasor measurement units (PMUs) can record and synchronize measurements 60 times per second to provide detailed analytical insight into grid functions. Volumes of such phasor measurements are then fitted with a GPS time stamp, creating the synchrophasor. Synchronized phasor measurements provide important insight into the state and flow of energy as well as the status of distribution equipment within an electric grid for real-time situational awareness, enabling utilities like Commonwealth Edison Co. (ComEd) to anticipate future potential system conditions.

The indications provided by synchrophasors will play an essential role in grid modernization in the decades to come. ComEd is implementing a number of modernization projects to ensure it is ready to meet clean energy goals and maintain a stable electric distribution system in a changing energy landscape. These projects blend strategies not only to help integrate existing equipment on the distribution system but also to prepare for future additions. Let’s take a deeper look at how the electric utility is investing in its systems to prepare for increased complexity, what challenges it has faced in implementing new technologies and how its blended approach anticipates future needs.

Increased System Visibility

PMU installations are a costly undertaking requiring engineering and project management expertise to avoid customer outages and specify expensive new equipment with which many engineers are not yet familiar. It might be worth reflecting first on the use case for synchrophasor measurement. Even if it is technically possible, why should utilities bother?

One reason ComEd believes synchrophasors are important is to help address the growing influence of distributed energy resources (DERs) in its service territory. Serving more than 4 million customers in Chicago and northern Illinois, U.S., the utility fields thousands of interconnect requests annually. The entire electric distribution industry is undergoing an era of transformative change as it seeks to achieve clean energy goals. To do this, electrical grids must be updated to enable increased penetration of alternative energy resources. The most efficient utilization happens at the point of load, and many customers are eager to install solar panels on their rooftops and batteries in their basements — yet DERs bring unprecedented complexity when scaled.

Power flow, frequency and overall stability can be impacted with the introduction of volatile energy sources at scale. With each new DER that comes on-line, the distinction between generation and distribution blurs and so does the need to leverage new technologies to increase levels of visibility on the medium-voltage distribution system.

Full Situational Awareness

Conventional one-way power flow was easier to manage — from transmission all the way downstream to relatively static and predictable distribution loads. What was once a straightforward, tiered hierarchy of power distribution is now in the stages of an intrinsic redesign that calls for increasing situational awareness. Pacific Northwest National Laboratory (PNNL) and the U.S. Department of Energy (DoE) define situational awareness in the power grid as “understanding the current environment and being able to accurately anticipate future problems to enable effective actions.” This means grid operators and management systems have the information necessary to make sense of an uncertain or dynamic situation.

With the earlier deployments of communication technologies like microwave, fiber and even 900-MHz radios, full situational awareness of the distribution system appeared possible. Operators gained visibility into circuit breakers. They could access loading information at medium-voltage substations, and even remote distribution centers appeared directly in the supervisory control and data acquisition (SCADA) console. These technologies represented a major accomplishment. Operators could see the majority of the distribution system and react to observed faults, load profiles and basic voltage concerns.

While telemetered distribution automation (DA) devices, power quality meters and advanced metering infrastructure (AMI) systems have been paramount in moving the needle on system visibility, a more nuanced plan is required as the grid grows more complex. ComEd averages thousands of interconnect requests annually. As new solar inverters and other DERs are interconnected, they account for a growing component of the connected generation to make a significant impact on the baseline load of the ComEd distribution system. Combined with over 7000 DA devices, the ComEd electric distribution network has become a dynamic system that differs markedly from the static model of conventional one-way power flow.

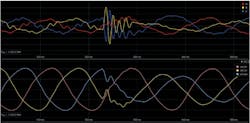

With volatile generation now on the system and an increased opportunity to automate the medium-voltage system, the need for situational awareness has grown exponentially. Transients, power quality blips and the sudden increase in distributed generation across the system present an immediate need for increased visibility. Operators and control platforms need enough visibility to know exactly what is happening on the system. Without an ability to observe the harmonics at a DER point of interconnection or a rapidly changing and automated medium-voltage system, such as a microgrid, they cannot fully understand the dynamics in the power systems they manage.

A Blended Approach

In its quest for full situational awareness, ComEd has engineered an approach to both meet the immediate needs of the present and plan for the system of the future. Considering the fundamental shift in the type of equipment needed to form this distribution network of the future, it is increasingly important to obtain data quickly and frequently. Given the inherently time-sensitive nature of synchrophasor measurements, ComEd’s PMU technologies supplement where conventional SCADA systems fall short.

Traditionally, a SCADA system collects polled data. A fast system aggregates data within a few seconds, and many data points may even experience delays of several minutes because of the nature of their communications solution. These timescales offer support for the more static parts of the ComEd system. However, events on the system can now transpire much faster — specifically, orders of magnitude faster. Inverter-based harmonics or the loss of a DER asset can happen on the order of cycles.

Like many utilities, ComEd is aligning to respond and prepare for system events and anomalies of an entirely different order of magnitude. A slow SCADA system may be incapable of diagnosing a problem, much less automating a response to it. Transient events such as flicker can occur and subside in a matter of cycles or milliseconds. Invisible to the SCADA system, but clearly captured within the synchrophasor realm, these events now become visible. Of particular concern is the risk that loss of a moderate generation asset could shift the direction of power flow at the edge without a moment’s notice.

To obtain situational awareness of a dynamic power system requires the electric utility to increase the rate at which data is collected while also pushing the monitoring capabilities out to the edges of the electrical network. Tracking dynamic elements requires a wider perspective in system visibility. In addition to substation transformers, buses and feeders, the same principles now are being applied along traditional distribution feeders.

Meeting the complexity of the overall system takes more than one simple approach. A well-coordinated strategy applying multiple distinct technologies is needed. Synchrophasors/PMUs, line sensors, SCADA and AMI meters all provide essential inputs to the task of increasing the situational awareness of visibility within the electric system. Working concurrently with each other, these technologies bring system operators closer to full situational awareness. The increased deployment of PMUs, in particular, is an exciting development for ComEd.

In late 2015, the utility developed a road map and strategy for the wide-scale operational use of PMUs in its transmission and distribution system. In the road map, the utility identified many distribution functions potentially suitable for synchrophasors. These uses include distribution linear state estimation and DER monitoring, along with distribution system operations for microgrids and automation. Incipient fault and failure detection using machine learning also is a possibility for synchrophasors.

These distribution functions will serve as crucial components of the future system as the penetration of DER increases. Synchrophasors can be used to estimate the real-time system voltage and power information, so system operators have the situational awareness needed to ensure correct and secure operations. At the distribution level, this may need to happen at sub-second rates instead of multi-minute rates, as in conventional state estimators used by energy management systems with higher voltage levels. These results enable system monitoring and control for advanced DA, enabling dynamic protection settings for the two-way-energy flow expected on the distribution grid, all supporting higher levels of reliability.

PMU Program

The journey to full situational awareness requires a multilayered strategy across the entire system hierarchy. Because PMU technology is available in several packages and across several classes of devices, it works to address multidimensional purposes. ComEd has taken an initial five-year programmatic approach to its distribution PMU deployments.

Starting with the end in mind, the distribution PMU program was launched in 2018 as a complement to PMU technology introduced on the transmission system just a few years prior. The program started with an aggressive deployment of over 60 PMU relay upgrades across seven key substations in 2018, the first program year, followed by a successful deployment of over 100 more distribution PMU installations in 2019.

In the short term, the front-heavy deployment strategy has prepared the groundwork and data necessary to advance into developing analytics and integrating software solutions. Long term, a full deployment will continue to be an iterative process driven by results collected from the first program years.

Substation Relays

Operating as a baseline for visibility on the distribution system, substation relays were the first layer of the ComEd system considered for PMU utilization. From the hundreds of substations in the system, the engineering team conducted a detailed review to determine the locations at which PMU technology could provide the most meaningful data. All substations were reviewed, and a weighted score was determined. Stations were screened first for baseline requirements such as physical space, fiber backhaul capacity and battery plant capacity. From there, elements like proposed DER growth, load profile and implementation cost were considered.

Within each station, specific distribution relays were identified by the engineering team to ascertain how full situational awareness at the distribution level could be obtained. In some substations, only a handful of feeders were included. In others, every feeder received its own relay upgrade. The medium-voltage feeders were screened and reviewed based on their load profiles: Do they have existing or future DER growth? Do they have any cogeneration facilities or transfer-trip schemes? Do they have any known power quality problems? In some cases, enabling PMU technology on the medium-voltage feeder relays was insufficient for situational awareness, so additional PMU technologies were enabled on bus and power transformer relays.

Inside the substation, ComEd took a proactive approach to standardizing the equipment and requirements for both transmission and PMU technologies. One of the most important keys to implementing new technologies successfully is standardization. By keeping individual elements simple and repeatable, they are easier to install, debug and maintain. In essence, a scalable PMU deployment requires the installation of phasor data concentrators (PDCs) and PMU-capable microprocessor relays.

With the future in mind, ComEd engineering and material teams created specific standards for both PMU-ready relay packages and PDCs. The result has been a relatively consistent topology that includes the placement of a PDC locally at each substation identified to receive PMU technology.

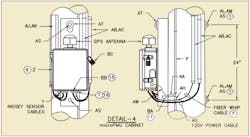

While the installation of equipment at a substation can become quite complex and require many iterations of prints, reviews and approvals, having a construction standard has proven to be extremely effective. All equipment has been specified in a detailed design, including a server cabinet, power distribution system, SEL-3573 PDC, networking equipment and GPS clock. Such consolidation enables ComEd to order all the equipment easily as a single, site-ready assembly from a vendor and have it shipped directly to the substation. The PDC assembly can handle future growth and helps to provide a visual indication of the equipment to operators within the station.

Many older relays on ComEd’s system do not have the capability to stream PMU data and must be upgraded to a modern package. Likewise, a standard design document was created for the upgrade of 12-kV relays. Many feeders chosen for PMU enhancements are conventional electromechanical relays. A standard design document ensures consistency is maintained across the system. It also expedites the design and review processes, as the practices remain similar from site to site.

With the incorporation of PMU technology at the substation, ComEd has been able to provide the first layer of distribution situational awareness. This serves as an effective baseline for viewing the system conditions. However, to meet the increasing needs for visibility, situational awareness must extend out along the distribution feeders themselves.

microPMU Devices

In addition to the substation relays on the feeder, bus and transformer relays, ComEd determined microPMU devices were needed at strategic locations at both the edges of and throughout distribution feeders. With the increase in DER on the distribution system, it has become increasingly important to improve the visibility of both generation and critical load at key interconnection points. Inverter-based generation can affect system frequency and voltage, so having PMU resolution offers the ability for engineers and emerging automation systems to respond both timely and accurately.

The microPMU device is a commercially available product, easily deployable on conventional distribution infrastructure. Consisting of an RTU about the size of a softball, battery backup and power supply, the entire unit is packaged inside a pole-mountable enclosure about the size of a conventional recloser control. Coupled with utility-specified dual-element 1400:1 potential transformer/600:1 current transformer Lindsey sensors connected to the distribution feeder, the microPMU captures synchrophasors on the order of 1% total vector error.

Feeder Monitoring

Another component in obtaining full situational awareness of the medium-voltage system includes monitoring the feeder mainline throughout the length of the feeder, which helps to provide complete visibility along the feeder. Today, ComEd is piloting PMU technology at the circuit edges and substation level.

Technologies to enable situational awareness from PMU technology along the mainline are still being investigated. Some key approaches for this could include installation of a microPMU device, as used at the feeder edges, or perhaps other telemetered devices with voltage and current sensors along with access to GPS time, such as an automatic recloser or capacitor bank.

Synchrophasor Deployment

One of the most significant aspects of ComEd’s successful PMU deployments has been its programmatic approach. Rather than treating the deployment of PMU technology as an iterative process, ComEd identified the technology as critical in helping to integrate and enable some of the future equipment on the distribution system.

As the penetration of DER — like energy storage, solar photovoltaics and other emerging technologies — increases, the need for enhanced monitoring and control capabilities will become more salient. PMU technology is vital in maintaining the stability of the distribution system while introducing volatile energy sources. The program engineering teams at ComEd apply technologies and ensure ongoing stability, both in the present and on the future system.

ComEd is now in its third year of deploying medium-voltage distribution PMU technology at the substation level. Approximately 70 relays are being added annually, with the total currently nearing 200 across the system. ComEd also has installed its first microPMU population along the feeder edges, beginning with an additional 25 PMU devices.

As with any project, there have been some interesting challenges along the way. Installing PMU technology has been no exception. One lesson learned from deployment is certain locations coincide with significant installation challenges. By selecting feeders and substations that connect to key venues or transportation hubs in the service territory, a significant coordination effort was required to avoid unacceptable outages. Months of advance notification and coordination were necessary to perform scheduled work requiring simple and short outages.

Game-Changing Technology

Historically, power distribution systems have relied on the work of electrical engineers on the generation side to maintain the performance of a finite set of large-scale power plants. Now, DERs are shifting the nature of power systems in ways that increase the complexity of the distribution side of the equation.

To keep pace with these changes, electric utilities must improve their ability to track the conditions in their power systems. With improved situational awareness, they can maintain the power quality and efficient voltages that have been the hallmark of well-managed electrical distribution. In these developments, PMUs are the fundamental technology and synchrophasors the principal unit of analysis. With these tools, power systems can become even more resilient than they already are amid the increasing DER connections. It truly is game-changing technology.

Ben Kregel has worked at Commonwealth Edison Co. for nearly 10 years and currently is a principal project manager in the grid modernization team, introducing synchrophasor technology to the distribution system. Prior to that, Kregel worked as a senior engineer in the distribution automation group, where he designed restoration schemes and implemented sensor technology. He focuses on grid infrastructure and intelligent devices on the smart grid, such as the first community energy storage project in Chicagoland. He studied electrical engineering at Iowa State University and holds a Professional Engineer license in Illinois.

Company Listings

Lindsey | https://lindsey-usa.com

Schweitzer Engineering Laboratories | https://selinc.com