Cooperation: The Key to Relay Protection System Reliability

The objective of protective relays and protective schemes is to protect electrical equipment such as transformers, lines, cables, bus bars, etc. during abnormal system conditions. Hence, protective relaying demands the utmost attention and diligence. However, when dealing with relay protection, protection engineers may inadvertently focus only on the relays. We talk about selecting appropriate relays, applying correct settings, checking out the wiring, ensuring correct interconnections, and performing effective tests.

However, we must realize that relay protection does not exist on an island. In addition to protective relays, substations contain other critical equipment including circuit breakers, current transformers (CTs), potential transformers (PTs), battery systems, and transformers.

In many large utilities, there is often a barrier between the relay department and the substation equipment department. The substation equipment, along with relays and relay protection schemes, are tested at regular intervals by the respective departments.

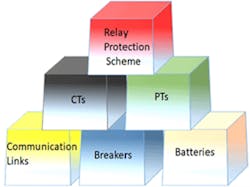

There is little realization regarding the critical dependency of relay protection on CTs, circuit breakers, etc. Hence, we should avoid isolating relay protection from CTs, PTs, breakers, and batteries. These are intertwined. Figure 1 illustrates the building blocks of the relay protection system: relays, current and voltage transformers, breakers, batteries, and communication links.

Failure in any one of these blocks will disrupt the relay protection scheme.

As mentioned above, utilities perform tests on CTs, PTs, the battery system, and circuit breakers. However, the results of periodic maintenance testing typically are not shared with relay protection engineers. As an example, protection staff may not be aware of newly developed sluggishness in breaker opening time or that the age of a CT may have led to deterioration of the saturation characteristics level. In some cases, we do notice an exchange of testing data of CTs, PTs, and circuit breakers is in the event of relay misoperation leading to forensic analysis. The team responsible for maintaining relay settings should be kept updated with these test results since access to this knowledge can impact the assumptions used to develop relay settings.

A Holistic Approach to Relay Protection

The relay protection scheme is the nucleus with all necessary logic built in; the other elements support relay protection schemes. CTs and PTs provide current and voltage inputs to the relays. The relays in turn provide input to energize the trip circuit resulting in opening of the breaker to isolate the faulted section of the power system. Station batteries, another building block of relay protection, energize the trip circuit with a DC supply. Understanding how each of these components contributes to proper operation of the relay protection scheme is essential to smooth operation of your protection system.

Relays

Engineers must select appropriate relays and provide appropriate settings. The relays and protection schemes must be tested at the time of commissioning, and subsequent maintenance must be performed at predefined intervals.

For relay testing, a software program that provides a comprehensive test environment flexible enough to accommodate technical and operational requirements — including for networks based on IEC 61850 standards — is ideal. The right software can help standardize elements of the relay testing program, reduce complexity, provide consistency, and capture and store important maintenance information and test records. This automation enables increased efficiency, accuracy, and productivity.

Any shortcomings in selection, setting, wiring, or testing can lead to misoperation of the relay protection scheme during abnormal system conditions. Some schemes include communication links between the relays at the two ends of a transmission line. End-to end testing must be performed to ensure correct operation of the protective relay scheme including receivers and transmitters.

Furthermore, digital substations built around the IEC 61850 standard have different testing needs than conventional substations. Testing in digital stations involves extensive verification of communication between the relays. There is a need to test the entire system as an entity, and system simulators can provide a solution for testing IEC 61850-based protection devices and schemes.

Current Transformers

The role of a CT is much simpler than the role of a relay. CTs simply provide current to the relays. The primary winding of the CT sees the actual current in the circuit while its secondary winding provides reduced current levels based on the ratio of the CT. Under normal load current, CTs reproduce currents correctly.

However, during short-circuit conditions when fault current is high, CTs may not reproduce the current accurately. Under such conditions, the current provided to the relay is normally lower than what it is expected. The degree of inaccuracy will depend on the magnitude of the short circuit current, X/R ratio, etc. This behavior of the CT is due to saturation of the CT core, which impacts the performance of simple overcurrent, distance, and differential relays.

It is very important to perform the following tests on CTs:

- CT excitation

- Current ratio

- Polarity

- Ratio and phase angle error

- Insulation resistance

- Winding resistance

- Burden check

Each utility determines the maintenance interval for testing based on its internal procedures.

Instruments designed specifically for testing CTs can help teams increase productivity and save time during commissioning. The ideal test set can perform CT excitation, current-ratio, polarity, and phase angle tests, measure insultation and winding resistance of the CT’s secondary windings, and measure the CT’s load burden. This can greatly increase productivity and save time during the commissioning stage.

In digital substations that implement process bus, the analog values of CT outputs are fed into a merging unit. The merging units provide equivalent digitized samples that are fed into IEC 61850-ready intelligent electronic devices (IEDs). IEDs are essentially microprocessor relays with significant built-in protection and communication logic. The IEC 61850-ready IEDs cannot accept analog signals from CTs and PTs, hence digitized samples must be provided. In this case, in addition to testing the CTs, the merging units must be tested as well.

Some merging units have built-in optical CTs and do not require input from conventional inductive CTs. These merging units require special testing tools and techniques.

Circuit Breakers

Circuit breakers must trip (open) when called upon by the protective relaying. If the dedicated breaker does not open, back-up protection will cause other related breakers to open in order to isolate the faulty equipment. However, the fault clearance by backup relaying will cause an outage of a larger part of the system; although this is not desirable, it is necessary. For this reason, it is essential for breakers to be maintained and tested appropriately to perform this function.

In addition to a breaker failing to open, issues can also be created if it takes longer than necessary to open the contacts. In protective schemes, breaker opening time is taken into consideration when setting a relay scheme. An actual contact opening time that exceeds the time that was used in the relay settings can cause unnecessary outage of a larger part of the system.

For example, when we set up a breaker failure scheme, we use the breaker opening time in the calculations. If the actual time turns out to be greater, several breakers will trip as part of a back-up scheme. This is an undesirable situation leading to the tripping of the entire bus. Similarly, when coordinating two overcurrent relays, miscoordination will occur if a breaker takes much longer to open. Hence, testing breakers is critical to ensure that they are operational within published parameters including the contact opening times.

The following tests must be run to ensure the integrity of circuit breakers:

- Breaker timing

- Static contact resistance

- Dynamic contact resistance

- Trip and close coil currents

- Minimum pickup voltage

- Travel time

- Power factor test

In addition, specific tests are conducted on SF6, vacuum, and air-blast breakers. A state-of-the-art circuit breaker analyzer can provide efficient and accurate performance measures for all types of circuit breakers. Digital circuit breaker analyzers can perform dynamic resistance tests and measure main contact and resistor contact time, stroke, velocity, over-travel, bounce-back, and contact wipes.

Battery System

The battery system plays a vital role in completing the sequence of tripping circuit breakers when called upon by the protective relaying scheme. The trip coil that is responsible for tripping the circuit breakers is energized when DC voltage is provided to it, and the protective relays provide the permissive. If relays provide the permissive but no DC power is available, the trip coil will not energize, and the breaker will not trip. Batteries are a crucial link in the chain of events and must be tested at regular intervals to ensure integrity.

To ensure the battery system is operational and will comply within specified parameters, the following tests are recommended:

1. Impedance

2. Intercell resistance

3. Voltage (battery float and cell float)

4. Specific gravity

5. Current

6. Temperature

7. Discharge testing

8. Infrared scanning

9. Capacity testing

Potential Transformers/CCVTs

The impact of inductive and capacitive potential transformers on relay performance is important. However, PTs/CCVTs do not undergo the type of duty that CTs undergo, and the performance of CTs has a much greater impact than those of PTs/CCVTs. During short circuit faults, the high current imposes extreme pressure on CTs. On the other hand, the voltage during short-circuit faults is depressed; therefore, the PTs do not experience any stress and continue performing as usual. Even with less stress imposed on PTs/CCVTs during short circuit, these devices are prone to damage due to other external and internal system conditions. Hence, they may not perform at the expected level of performance. PTs/CCVTs are as critical as CTs in ensuring correct operation of the relay protection scheme.

The recommended tests include:

- Voltage ratio

- Polarity

- Ratio and phase angle error

- Insulation resistance

- Winding resistance

- Burden check

- Power factor Test

The tests to be conducted and the related maintenance interval are listed in the maintenance procedures. In general, the maintenance interval for PTs/CCVTs is much longer than those for CTs.

Communication Links

Communication is a critical link in several protection schemes. In high-speed communication-assisted protection schemes, communications between the two substations are connected by a transmission line. The relaying at each end depends on information received from the other end to operate correctly. The medium used for communication can be fiber optic, power line carrier, microwave, etc., with transmitters and receivers installed at each end. To test such relay schemes, utilities conduct end-to-end testing to ensure the scheme works appropriately and this testing includes both the transmitters and receivers.

In a digital substation designed per the IEC 61850 standard, the IEDs communicate with each other via GOOSE (generic object-oriented substation event) and SV (sampled value) protocols. GOOSE/SV is a Layer 2 protocol, i.e. messages are transported over Ethernet. In a conventional station, communication between IEDs is accomplished via point-to-point wiring. Hence, communication assumes a much bigger role in a digital substation, and the relay protection scheme relies heavily on proper communication. Testing such protection schemes involves extensive debugging of the communication network.

Relay Protection is a multifaceted scheme comprising of relays, breakers, CTs/PTs/CCVTs, batteries, and communication links. Effective relay protection is achieved only if all constituent components work together and perform within acceptable level of performance.

Ed Khan is Director of Protection R&D and Protection Training at Doble. In this capacity, he manages and conducts the relay protection training program. Prior to joining Doble fourteen years ago, Ed worked for GE, ABB, SEL, KEMA, and others in various capacities. He has 38 years of experience in system studies, protection applications, relay design, power plant design, teaching, and product management. Ed specialty is product development, protection, harmonic analysis, harmonic filter design, stability studies, real-time digital simulations, generator protection, and more. He holds an MS in electrical engineering from Texas A&M University.

This article was provided by the InterNational Electrical Testing Association. NETA was formed in 1972 to establish uniform testing procedures for electrical equipment and systems. Today the association accredits electrical testing companies; certifies electrical testing technicians; publishes the ANSI/NETA Standards for Acceptance Testing, Maintenance Testing, Commissioning, and the Certification of Electrical Test Technicians; and provides training through its annual PowerTest Conference and library of educational resources.