In 1994, Bolivia was an early reformer of the electricity sector in Latin America, deregulating the former vertically integrated industry. After privatization, ENDE Transmisión S.A. became part of Union Fenosa, a Spanish electric utility, from July 1997 to 2002. Then it came under the administration of Red Eléctrica de España, the Spanish transmission system operator, from 2002 to 2012. Subsequently, because of a lack of private investment, the government of the Plurinational State of Bolivia renationalized the transmission system in May 2012 in favor of ENDE, recovering this national infrastructure utility for the country.

A subsidiary of ENDE Corp., ENDE Transmisión operates as a transmission utility in the National Interconnected System (SIN), enabling the connection of generation plants with distribution networks and facilities of nonregulated customers located in different points of the Trunk System of Interconnection (STI). The utility is responsible for operation of 86% of the SIN transmission, which includes 61 grid substations and a transmission system some 4667 km (2900 miles) in length. With operating voltages of 69 kV, 115 kV and 230 kV, the transmission system spans eight Bolivian provinces and states, namely, Cochabamba, La Paz, Santa Cruz, Oruro, Potosí, Chuquisaca, Tarija and Beni. The maximum demand on the SIN in 2017 was 1459 (MW), an increase of 1.74% compared with 2016. During the same period, energy consumption increased by 2.82%, to 8614 GWh.

The bulk transmission of electrical energy is a cornerstone of modern society, and customers now expect efficient and reliable supply networks. Security of supply is of vital importance, so operation and maintenance of the transmission system’s fault performance is paramount.

Transmission System Security

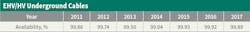

ENDE Transmisión’s system comprises mainly overhead lines, including some relatively short lengths of underground cable that are more acceptable environmentally and only have minimum right-of-way requirements. They also are less susceptible to adverse weather conditions and have a superior fault performance. The principal disadvantage of underground cables is the capital and installation costs, fault location and repair costs. Intense maintenance work on the transmission system has translated into a high-quality reliable service, resulting in operational availability of the transmission facilities regularly exceeding 99%.

Since its inception, ENDE Transmisión has been responsible for testing all extra-high-voltage (EHV) and high-voltage (HV) cables installed on new projects and existing cables within the Bolivian territory. Initially, and for many years, the utility used an overseas service company to undertake commissioning and routine testing of the underground cables. However, the company performing this work used equipment the utility considered to be bulky and not the most efficient solution. Additionally, the service contract proved to be very expensive.

For example, the commissioning tests included the soak test, whereby the unloaded cables were subject to the applied voltage for a period of 24 hours. The test results generally were found to be inconclusive, failing to provide a satisfactory assessment of the underground cable installations.

It became evident ENDE Transmisión required a better and more reliable way to test its HV power cable installations.

The utility decided it would be preferable to invest in its own equipment. It would give the utility more flexibility as well as a greater understanding of the condition of the HV underground cables and cost savings when compared with the services and costs of using an external contractor. By taking over responsibility for the test procedures, the utility also could improve its customer service.

Alternative Cable Testing

ENDE Transmisión examined several different cable testing options, including resonant voltage wave tests and nominal voltage energizing tests. The utility also reviewed and analyzed the IEC 60840 standard, which defines the commissioning test parameters for medium-voltage and HV cables.

ENDE Transmisión sought a testing unit that offered a damped alternating-current voltage technology, which was more advanced than the heavy resonant systems used by the external contractor. It also was interested in learning more about the diagnostic tests that could be applied to EHV and HV cables. After researching the cable testing equipment commercially available and comparing it with equipment in use at the utility, ENDE Transmisión decided to invest in the DAC300 test set manufactured by Megger. This unit not only offered the most technologically advanced options, but it also was backed by a first-rate presale and post-sale service.

Megger DAC300 test equipment being used on acceptance testing for new EHV cable terminations in an ENDE Transmisión grid substation in accordance with IEEE 400.4.

The DAC300 test set can identify, evaluate and locate partial-discharge faults in cable insulation as well as accessories of all types associated with EHV and HV underground cables. An indication of incipient faults in cross-linked polyethylene (XLPE) insulation, partial-discharge activity is regarded as one of the best early warnings of the deterioration of HV and MV cable insulation.

Finalizing connections of DAC test equipment to EHV cable terminations in switchyard of grid substation prior to cable commissioning tests.

Harsh Conditions

An example of cable testing in harsh conditions arose when it proved necessary to test the 115-kV, 20-km (12.4-mile) long underground cable supplying a lithium plant situated some 3700 m (12,140 ft) above sea level. A 115-kV overhead transmission line is connected to the underground cable installed in these unique conditions to supply the Yacimientos de Litio Bolivia (YLB) lithium plant, located in the middle of the Salar de Uyuni, one of the largest lithium reserves in the world. This area faces extreme adverse weather conditions because of its arid climate, salty desert and unforgiving sunshine, conditions that corrode everything.

In view of the demanding on-site weather conditions, it was important to complete all test procedures in minimal time. Therefore, it was important for ENDE Transmisión field staff to be equipped with the DAC300 test set, as it produces high-quality test results and diagnoses problems easily, accurately and quickly.

Aside from the climate, this project had additional challenges. These included harmonizing the customer’s contracts and documents in different languages and legislations as well as setting up the test set on-site for the length of HV underground cable.

The principal advantages of this test set are its compactness, extreme transportability and use of little power. It is relatively easy to set up on-site, making it ideal for all applications. This unit really has proved beneficial not only because it saves ENDE Transmisión time and money, but it also provides the accurate test results required.

Future Reliability

With a better testing and diagnostic tool in hand, ENDE Transmisión has been able to reduce testing time and costs. It also now can offer services in response to customer requests. The utility is confident it can monitor EHV and HV cables more effectively, ensuring the Bolivian population will continue to have a reliable power supply in the future.

For more information:

ENDE Transmisión | www.endetransmision.bo

Megger | https://megger.com