The Life and Impact of FISR and Fault Location at Alabama Power

One of the benefits of having a single platform is the situational awareness provided. The status of telemetered devices, system loading, the as-switched model, tagging, etc., is easily accessible and presented to system operators. In GE Digital’s integrated ADMS solution, advanced applications take advantage of this information by enabling analytics and switching functions. Alabama Power has enabled Fault Isolation and Service Restoration (FISR) and Fault Location (FL), each one helping make the distribution grid more resilient and enhancing reliability.

The FISR System

FISR is a model-based application that dynamically analyzes emerging outages to develop restoration plans, checks the feasibility of these plans against real-time power flow results, and implements the plan using SCADA controls. Alabama Power has configured FISR to automatically execute in closed-loop mode when it is triggered by a fault event, using SCADA-reported fault targets to determine which sections to isolate and which ones to restore.

When developing restoration plans, FISR will dynamically check for voltage violations and overloads to avoid implementing plans that could potentially cause issues. In addition, FISR searches for system tags that indicate crew work is in progress and excludes considering switches that could impact that work. Since there can potentially be several valid plans that restore customers’ service, FISR ranks plans based on the number of customers restored, amount of load restored, optimal loading and voltage ranges, etc. Once FISR finds the most valid plan, it sends SCADA messages to automatically trip and close switches to implement restoration steps. Once the restoration plan is completed, operators and field crews begin patrolling to locate the fault and make repairs. The effectiveness of FISR increases as more field devices are added to the distribution system.

Quickly Restoring Power

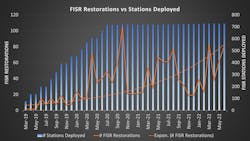

Since its inception in 2018, FISR has been a catalyst for improving Alabama Power’s restoration efforts. In total, FISR has implemented 1,488 plans, which restored power to over 724,000 customers through July 2022. Perhaps more impressive is the timeframe in which the plan evaluation and implementation took place. On average in 2021, FISR restored customers in 19 seconds after device lockout for two-step plans, 39 seconds for four-step plans and 58 seconds for six-step plans.

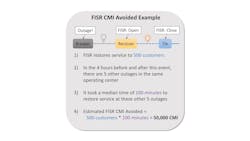

Due to the quick restoration for Alabama Power’s customers, FISR has helped reduce the company’s Customer Minutes of Interruption (CMI) and System Average Interruption Duration Index (SAIDI). FISR has helped Alabama Power customers avoid an estimated 260 million CMI through July 2022. In addition, FISR has helped Alabama Power avoid 7.9% SAIDI year-to-month as of July 2022. There is currently little industry consensus on estimating how long an outage would have lasted had FISR or other schemes not quickly acted. Estimating the potential outage duration FISR helped avoid is important to calculating SAIDI- and CMI-avoided numbers. Alabama Power’s method involves taking the median outage duration from all primary outages in the same operating center within four hours of an FISR restoration. This method considers different restoration estimates from urban versus rural locales, storm versus blue sky days, and day versus night responses.

One of the best scenarios where FISR showcases its capabilities is during the unpredictable hurricane season. According to the National Weather Service, although 14 tropical storms impacted Alabama from 2010 to 2022, seven of those storms impacted Alabama in a just a two-year span. Since it can potentially take several weeks to completely rebuild infrastructure after a major hurricane, Alabama Power leverages every available tool in these tough situations to maintain reliable service for its customers. This two-year span was especially challenging for many reasons, but FISR made a positive contribution regardless of the changing conditions day-to-day.

In October 2020, FISR was put to the test when Hurricane Zeta impacted Alabama. Approximately 433,000 customers were without power at its peak, with 6,000 spans of wire down, 1,250 poles broken and 500 transformers destroyed. FISR implemented 84 restoration plans, restoring 45,991 customers. Approximately 64% of the sections FISR restored remained energized through the remainder of the outage/storm, which has fueled discussion on the value of keeping FISR enabled during a large storm versus keeping the system static to simplify restoration efforts.

Running Tests

In June 2021, Alabama Power enabled FISR to trigger for loss of voltage (LOV) due to a loss of transmission source at a substation. Before LOV was implemented, when a distribution substation became de-energized, distribution system operators would have to contact their counterparts in the transmission control center to verify that a substation was in fact de-energized. After the verification, the distribution operators would formulate a plan to individually trip the breakers and restore power from adjacent feeders where feasible.

When a substation loses voltage today, however, FISR LOV verifies that both the substation bus voltage and the load current on each feeder are under user-configured thresholds, and that no fault targets or breakers have changed status. Once satisfied that this must be an unexplained loss of transmission source, FISR LOV runs the same dynamic plan and power-flow-checking algorithm to restore customers from adjacent energized substations. FISR LOV is much faster and minimizes the potential errors an operator may make, while considering all possible voltage violations and overloads to prevent an operator plan from making things worse. In addition to the normal FISR operations, FISR LOV has had a massive impact, implementing 26 plans that have restored over 37,500 customers since its inception.

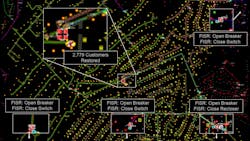

Finding Fault

In addition to the benefits of FISR, fault location provides a visual aid to assist users in locating faulted line segments by painting halos around distribution conductors on the ADMS geographic display. A painted halo appears on the ADMS geographic map as if the system has highlighted a section of de-energized line with a red highlighter, drawing attention to the location of the predicted fault. Fault location uses the SCADA-reported fault targets and fault currents, as well as the as-switched model to calculate the likely location of a fault.

Once the line is re-energized, the halos will clear every 30 minutes to indicate that faults are no longer present. Fault location is an extremely helpful tool since it helps operators quickly identify the location of a fault and identify the issue, resulting in more efficient evaluations and quicker restoration times. Since its implementation in 2018, Fault location has painted 74,654 halos on the ADMS geographic, which users report to have a 90% accuracy rate. On average, each halo reduces patrol distance by 1.84 miles and outage duration by an average of 8.1%.

Lessons

FISR has had an astounding impact on our distribution system, but this was only achieved by many power delivery departments working together and changing our philosophy on how the distribution system should behave. There were many contributions made from our teams, especially in the areas of deployment, model cleanup and ADMS support.

Since modeling data now has real-world impacts, the quality of distribution models needed to improve. During this cleanup effort we had many improvements to our system made or corrected, including over 9,375 wires field-checked/updated in GIS, 1,629 fuse sizes corrected, 443 transformer sizes corrected, 217,306 AMI meters moved to the correct phase, 76,400 power-flow violations corrected, and 138 bad SCADA sensors remedied.

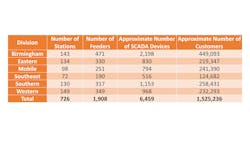

FISR deployment across the system did not occur all at once; instead, Alabama Power deployed FISR at 60 substations at a time. This measured approach allowed time for model cleanup and testing as we worked toward our goal of 726 enabled substations. Year-to-month July 2022, FISR was unable to implement 17% of the plans it found for outages. The reasons vary from devices failing to operate in the field, FISR finding valid overload and voltage violations and deferring for an operator to review, or modeling issues.

This process took about 18 months and generated other paybacks that extended beyond advanced applications. Alabama Power identified weak points in the system, such as wire sizes that needed to be upgraded. We improved OMS outage predictions due to more correct phasing of customers and improved the analytics to identify future investments we can make in maintaining our grid.

Next Steps

The FISR and fault location applications have not only changed the way Alabama Power approaches data and its real-world impacts, but also how the company operates its distribution system. With FISR automatically sectionalizing and restoring customers after a sustained fault, and fault location painting halos to help narrow down patrol areas even more for crews, Alabama Power can provide more reliable service for the communities it serves.

The combined benefits of FISR and fault location are enabling Alabama Power to work toward a smarter grid, building Alabama’s energy future with centralized intelligence. There are many more advanced applications in GE Digital’s ADMS solution, and Alabama Power is actively working to test and deploy those to improve reliability for its customers.

William Dykes ([email protected]) is an ADMS Advanced Applications engineer for Alabama Power, providing support for Distribution Power Flow, Fault Location, and FISR and other Advanced Apps. He earned his Bachelor’s in engineering in 2017 from Mississippi State University. Before Working with Advanced Applications, he was a Distribution System Operator for 3 years and a Transmission System Operator for 1 year.

About the Author

William Dykes

William Dykes ([email protected]) is an advanced distribution management system engineer for Alabama Power who provides support for that utility's distribution power flow, fault location, fault isolation and service restoration system and other advanced application. Dykes earned his bachelor's degree in engineering in 2017 from Mississippi State University and worked as a distribution system operator and a transmission system operator for several years before working with advanced applications.