California’s wildfire risk has increased in recent years because of climate change, drought, increased development in the wildland-urban interface and the significant buildup of fuel, including on federal and state forest lands. The full magnitude of the increased threat and significance of its consequences did not become apparent until 2017, when the state experienced five of the most destructive fires in its history. This was compounded in 2018 by three more such fires. Eight of the 20 most destructive wildfires in California’s history occurred in those two years, destroying more than 31,000 structures — double the number consumed by the other 12 fires. California’s wildfire risk had increased to the point where the safety of its communities required additional measures.

In recent years, Southern California Edison (SCE) has focused most of its wildfire mitigation projects around the prevention of electrical faults by such measures as installing covered conductor and insulating spacers between phase conductors. These methods are highly effective at reducing the probability of ignition by fault avoidance, particularly for contact-related faults and those involving two or more phase conductors. These measures prevent the majority of but not all incidents, particularly equipment-failure-related faults.

SCE needed additional transformative measures to minimize the chance of a fire when an unforeseen event occurs, such as a car hitting a pole, a transformer failing from a manufacturing defect or a large tree falling into a power line. Therefore, it benchmarked with utilities in the Australian state of Victoria, one of the most fire-prone areas in the world, to learn how rapid earth fault current limiters (REFCLs) can reduce the risk of ignition by faults involving a single phase conductor.

Victorian Learnings

Extensive testing of REFCLs by Victorian utilities has resulted in a set of criteria that, if followed, can reduce the risk of ignition for faults involving a single phase conductor by at least 90%.

These criteria start with the requirement of being able to detect faults as small as a half ampere and otherwise concern the speed at which voltage must be reduced once a fault is detected to prevent ignition.

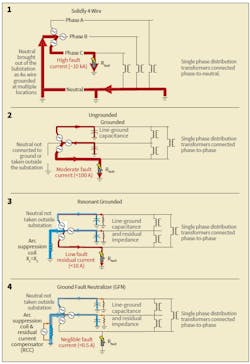

The Victorian utilities then proceeded to test the best commercially available products capable of reducing ground current. These included resonant grounding with an arc-suppression coil, ground-fault neutralizers that use an inverter in parallel with an arc-suppression coil to further reduce the fault current, and faulted phase earthing, where the faulted phase is grounded immediately after a fault is detected.

Unlike with circuit breakers and fuses that have extremely sensitive settings, REFCL technologies have the advantage that power still can be provided to customers during ground fault events. Electric service reliability improvements can be realized with this system, most notably the lack of circuit interruptions or outages for faults transient in nature, as commonly seen with wildlife contact. Only when a fault is permanent does a circuit breaker open to deenergize the customers. This means the system can increase the sensitivity of the protection and electric service reliability at the same time.

Of the REFCL devices tested, only the ground fault neutralizer met all the Victorian ignition criteria. Based on the success of that testing in the laboratory environment, the major utilities were mandated to convert 45 substations. This work is more than one-third complete, with Australian utilities having successfully converted 21 substations feeding more than 5500 miles (8851 km) of 22-kV circuitry.

Three-Wire Circuits

While SCE actively is investigating the application of ground fault neutralizers for fire-ignition prevention, some limitations make it difficult to deploy on a large scale. One disadvantage of REFCL systems is, when in operation, the good phases experience overvoltage to the phase-to-phase voltage of the system at the same time the faulted conductor is deenergized. This has little impact on most new distribution equipment, as it has significant insulation margin, but older equipment sometimes must be replaced as part of the conversion.

The technology also only works if all the circuits fed by the substation bus are three-wire circuits without a neutral. This requirement is a prohibitive limitation for some, as most North American utilities build primarily four-wire circuits. However, SCE and, to some extent, other California utilities are well positioned as they built a grid with more three-wire distribution systems than are generally found in North American electric utilities. This practice is like that of most European and Australian utilities, where distribution transformers typically are connected between phases and the neutral does not leave the substation.

Even with the large amount of three-wire distribution lines SCE operates, major upgrades would be required for deployment. Much of the SCE’s three-wire circuitry is outside the high-risk areas yet still must be modified to enable the ground fault neutralizer to operate. Often, this means replacing vintage equipment no longer in good enough condition to withstand the overvoltages. In some cases though, particularly with phase-to-neutral connected distribution transformers, this will require replacing equipment that otherwise would be good for decades of continued service. This conversion of four-wire to three-wire circuitry adds considerable scope at SCE beyond what was required in Australia because all 22-kV transformers in Victoria are connected phase to phase.

SCE also shares many other implementation challenges faced by Victorian utilities, including balancing system capacitance, substation physical footprint constraints and a host of equipment-specific issues, such as surge arrester and potential transformer ratings to name a few. For these reasons, SCE also has investigated other alternative technologies with similar benefits as part of its commitment to California’s Wildfire Mitigation Plan.

Resonant Grounded Substations

The most common REFCL technology is resonant grounding, where an arc-suppression coil (Petersen coil) is connected to the transformer neutral to reduce fault currents to less than one-tenth of that found on an ungrounded system. Resonant grounding has been applied to thousands of substations and is particularly common in central Europe, where it is used to increase the reliability and safety impacts of ground faults. Unfortunately, resonant grounding at the substation was determined by the Victorian testing to be insufficient at reducing fault current to a level that would prevent ignitions. Even with currents under 10 A, contact from vegetation or dry grass consistently resulted in ignition.

When comparing the SCE system to the 22-kV distribution systems in Victoria, it was noted Australian utilities operate higher system voltages and longer distribution lines. Therefore, the fault current for resonant grounded distribution networks was found to be much lower for SCE than it was in Victoria. On some SCE substations, resonant grounding alone reduced the fault current to approximately 1 A. Where relays were timed to clear faults within two seconds, the Victorian ignition targets all were capable of being met.

Despite resonant grounding being an attractive option for these small substations, it presents a significant technical challenge. The faulted circuit must be identified with minimal fault current. Few products on the market even claim to be able to detect such small magnitude faults. While SCE is converting a substation to resonant grounding to determine whether implementation is practical, the protection is only certain to identify the appropriate circuit for substations with only one distribution line per transformer. In these substations, it is not necessary to determine the circuit on which a fault occurs; the circuit breaker can be opened just knowing a fault is present. The presence of even extremely low magnitude faults can be determined reliably with a measurement of .

Isolation Transformer

To further expand the range of circuits on which REFCL can be deployed economically, SCE developed a viable way of using resonant grounding for prevention of ignition by creating the resonant ground on the load side of an isolation transformer (patent pending). In this case, an isolation transformer is installed near the boundary of a high-risk fire area so all circuitry beyond the transformer is covered.

Resonant grounding an isolation transformer near the edge of a high-risk area rather than at the substation offers several advantages:

- Single line to ground fault current is reduced compared to installing the arc-suppression coil at the substation. When installed in the substation, the fault current is the sum of charging current of all circuits fed by the substation bus. When applied at an isolation transformer, the current feeding the fault is only the charging current of the circuitry downstream from the isolation transformer.

- Whenever a fault occurs, the overvoltage only happens on the load side of the isolation transformer, rather than every circuit fed by the substation bus. This reduces the conversion cost substantially, as four-wire circuitry with phase-to-neutral connected transformers and equipment not rated for the overvoltages can remain on the lower fire-risk parts of the circuit.

- Protection is simplified. It is challenging to determine which circuit a fault is on when the fault current is so low. When the isolation transformer is resonant grounded, protection for ground faults can consist entirely of voltage measurement on the neutral. When the voltage is above a set point, the circuit trips.

To scale this system to a wide range of circuits, additional problems need to be addressed. If a typical delta-wye isolation transformer bank were used, a phase angle difference would prevent paralleling with other circuits. This would limit applications to circuits without normally open ties to other circuits, and delta-delta or delta-zigzag transformers would be required. Also, to address aesthetic concerns, a pad-mounted solution would need to be designed for both the transformer and arc-suppression coil.

Ignition Testing

Before making the investment to develop and deploy the resonant grounding system with an isolation transformer, SCE had to empirically validate the system was effective in reducing incidence of ignition. While initial calculations suggested it would be effective, the lack of experience with such systems created some uncertainty in how they would perform. Thus, the utility decided to install and resonant ground an isolation transformer at its equipment demonstration and evaluation facility (EDEF).

This testing first showed the system could meet the Victorian REFCL criteria. The protection consistently opened the circuit within two seconds and, until that point, the natural reduction in voltage from resonant grounding was sufficient to meet the other requirement. This was the best evidence the system prevents ignitions in at least 90% of single line to ground faults, because the criteria are based on hundreds of tests in worst-case fire conditions.

The ignition criteria were developed with a ground fault neutralizer in mind though, so SCE also wanted to confirm the results by reproducing common ignition scenarios. Down wires in contact with dry grass and phase-to-ground contact from tree branches, guy wires and Mylar balloons were chosen as representative of ignitions seen in California.

In the faults with down wires in grass, two out of 24 tests resulted in ignition, one from only 126 mA into the grass. Even this probably understates the effectiveness though. Real-world scenarios typically result in a much longer length of conductor in contact with the ground than the 14.5-inch (368-mm) test cell. The longer length acts to reduce the current density and voltage on the conductor. Therefore, these results are likely to be conservative.

No ignitions were produced in any of the 29 phase-to-ground contact tests performed. No burning wood or falling molten metal particles larger than 2 mm were observed in any of the tests. Faults that were inches above dry grass did not even scorch the grass. The fault energy was low enough that, in some tests, the metallic balloons made contact for up to 15 minutes without even popping! Brief (approximately 2-msec) faults occurred and self-extinguished until enough metallic coating was removed that arcing stopped entirely.

REFCL Pilots

This testing demonstrated resonant grounding can be a viable way to prevent fires if installed on a small substation or an isolation transformer. This is only the third technology demonstrated to be able to meet the Victorian REFCL ignition criteria.

As a result of these successes, SCE chose to add three REFCL pilots to its 2020-2022 wildfire mitigation plan: A ground fault neutralizer that builds directly on the work in Australia, a resonant grounded substation and an isolation transformer.

Initial rollout of the isolation transformer will be with ungrounded delta-wye connected transformers. This enables existing hardware to be used to meet the REFCL criteria on a section of a circuit. Development is ongoing to obtain delta-zigzag pad-mount transformers and arc-suppression coils sized to the distribution application. This technology will enable scaling to dozens or hundreds of installations.

Acknowledgements

The authors gratefully acknowledge the contributions of Jim Palma, Gabriel Andaya, Matthew Webster, Brendan Kirkpatrick, Benjamin Garcia, Michael Harrington, Michael Hughes, Austin Fresquez, Arianna Ojeda, Joshua Park, Thuan Tran, Tucker Straud, Kenneth House, Mark Garringer, Andrew Rott, Jose Amaral, Manuel Frey and Allison Auld-Hill for helping to make new ideas a reality and ensuring REFCL testing was completed safely.

The authors gratefully acknowledge the contributions of David Wilkinson, Brodie Stephenson and Tony Marxsen for providing information on the REFCL program in Victoria.

Jesse Rorabaugh ([email protected]), P.E., is a senior engineer at Southern California Edison (SCE). He received his bachelor’s degree at California State University, Fresno with a triple major in physics, chemistry and biology followed by a master’s degree in biomedical engineering from Cornell University and a professional engineer license as an electrical engineer in California. He is an active IEEE member and serves as chair for the G4 working group responsible for IEEE Std 1246 Guide for Temporary Protective Grounding Systems Used in Substations and Std 1268 Guide for Safety in the Installation of Mobile Substation Equipment as well as vice chair for the G9 working group responsible for IEEE Std 837 Standard for Qualifying Permanent Connections Used in Substation Grounding.

Andrew Swisher ([email protected]), P.E., is a consulting engineer at SCE. He received his bachelor’s degree from California State Polytechnic University at Pomona in electrical and computer engineering with a certification in power engineering followed by a master’s degree from the University of Idaho, Moscow with a certification in power system protection and relaying. Swisher is a licensed professional engineer registered as an electrical engineer in California.